- 2021-12-1

- best seaside towns uk 2021

CASTING STAINLESS STEEL. Qingdao Refidus has rich experience in precision casting impeller manufacturing in China. Stainless Foundry & Engineering is a One Stop Shop. The leading Stainless Steel Casting Manufacturers collect the casts in a basket and put them into a shot blasting machine. Sitaram Engineering Inc. Black Ss 304,Ss 316 Stainless Steel Casting, Weight: 1 Kg, Grade: Ss 304,316. DIN 17445. Shree Krishna Induction Pvt Ltd. It is the most widely used stainless steel casting material. ₹ 500 / 1kg. Stainless steel casting is a well-known method due to the sophisticated shapes it can produce. @article{osti_5893207, title = {Centrifugal castings of stainless steel spiked with radioactive tracers}, author = {Beeston, J M and Larsen, M M}, abstractNote = {The results of making centrifugal castings of stainless steel spiked with radioactive tracers are presented in this report. 304 stainless steel is the most common type of steel. Stainless steel casting involves heating the stainless steel material to above its melting point and introducing the material into a mould where it solidifies into the required shape. The weight of these stainless steel investment castings ranges from 1 ounce to 250 pounds. News. Surface satin finish: A 240 grit finish on stainless steel forging is the most common requirement for surface stain finish on stainless steel parts. Our stainless steel is very aesthetic in nature and its attractive look appeals to the eyes and vision of the customers. Or you can use the stainless-steel 312 rod if the cast steel composition is unknown. Mirror polished stainless steel forging will look shining, like mirror. In addition, in all cases it is magnetic. Stainless steel parts are also produced with sand casting, a process where sand is used to create a mold. Our Chrome Alloy Cast Valves inventory is unsurpassed and is considered one of the most extensive chrome inventories in the world! 1.4008. Stainless Steel Cast Valves. Steel is an alloy consisting of iron (Fe) and carbon (C), where the term ‘steel’ is used for iron alloys with a limited amount of carbon (less than 1,9%). It has better temperature resistance than 304 stainless steel. The basic composition of austenitic stainless steel casting grade is 18% chromium and 8% nickel. This enhances their corrosion resistance and modifies the structure from ferritic to austenitic. We cast stainless steel Grade 304, 316 and 316L. The concern here is to avoid warping the casting part and keep its original dimensions and shape. For more corrosive applications, duplex grades of stainless including ASTM A890 and A995/cast grades of 2205 and 2507, among others. 1) Melting and Casting. ₹ 430 / Kg. Stainless steel casting has numerous reasons to be used by industrials, manufacturers, and engineers. What Is Stainless steel Casting? Lock, hardware accessories. Spec of Stainless steel casting. There are basically 3 steel grades (types of steel) that are used when it comes to product manufacturing:Carbon SteelAlloy SteelStainless Steel Metal casting is an amazing profession, but it is not easy at all to get into. there are different materials for the impeller, such as bronze and stainless steel. Welcome to the premier industrial resource for Stainless Steel Castings . The stainless steel investment casting process is used to create components for a range of industries including aerospace, petrochemical, medical, automotive, and food and dairy. Neuland is a company manufacturing and marketing of metal products for nearly 20 years. CA15 is the designation in both the ACI and ASTM systems for this material. Internal passageways including intricate structures can be included in sand casting by adding cores. It has the highest ductility among cast martensitic stainless steels. Sand castings are typically at least partially machined before use. View All Industries All Industries Pump & Valve Power Generation Centrifugal castings in stainless steels, bronze alloys, aluminum, and iron alloys, from 50 pounds to over 20 tons. For casting, the two most common types of materials are cast iron and stainless steel. This makes sand casting a popular choice for pump and valve applications. Stainless steel grill grates are definitely easier to clean out after each use. Cited properties are appropriate for the normalized and tempered condition. Unit weight range from 100g to 20tons. It is commonly used in cutlery, petroleum refining, petrochemical processing, and marine environments, etc. The 303 stainless steel can be machined more easily than 304 stainless steel by adding a small amount of sulfur and phosphorus. Investment Casting As highly versatile casting process, Investment Casting has for some time been perceived as a comparatively expensive process. Upgrade any Kokomo Grill standard Pipe burner to the Lifetime warranty Cast Stainless Steel Burner Universal Burner for 3,4,5 Burner Classic and Pro Series 304 Cast Stainless Steel Burner 18,000 BTU Burner 416 Stainless Steel Investment Casting Process 1. Unlike carbon and alloy steel, stainless steel castings require little or no additional surface finishing. Common markets for stainless steel investment castings include defense, oil and gas, medical and many more. High alloy and stainless steel alloys are high-value alloys that are suitable for many applications. Stainless steel casting involves heating steel above melting point and introducing the material into a mould, from where it solidifies into the required shape. Stainless steel accessories of various materials. It is a low-cut or no-cutting casting process. Stainless Steel Lost Wax Casting. Meeting our customers’ growing demand for large high-quality steel castings, Barron’s unique process allows us to manufacture large stainless steel investment castings up to 25 inches or 64 cm and 150 pounds or 68 kg. The 400-series group of stainless steels contain 11-27% chromium, up to about 1% carbon, and 2.5% nickel maximum. Alloy Search. The grades of stainless steel castings Signicast most often produces respond to heat treatment and can be supplied with a predominantly martensitic microstructure in a wide range of strength and hardness. Stainless steel casting 410 has high strength, hardness and good corrosion resistance. Wrought stainless steel starts out at a steel mill, where continuous casters make stainless into ingots, blooms, billets, or slabs. Stainless Steel Casting. It belongs to the general model, which is 18/8 stainless steel. As a widely used steel, it has good corrosion resistance, heat resistance, low-temperature strength, and mechanical properties; it has good hot workability such as stamping and bending, and no heat treatment hardening phenomenon (non-magnetic, Use temperature -196℃~800℃). We specialize in investment castings by casting a wide variety of alloys including stainless steel, duplex stainless steel, carbon steel, titanium, aluminum. These pipe fittings are for air, oil, gas, water & steam service. ForceBeyond offers superior quality die castings, investment castings, super duplex stainless steel castings, hot forgings, cold forgings, sand castings to industries including automotive, food dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical industry, aerospace, submarine and others On the other hand, stainless steel has a big advantage in that it is more resistant to impact than cast iron. 316 316L stainless steel is austenitic stainless steel. (8,165 kg). Grade CA-15. We provide custom stainless steel castings for industries and applications including automotive, food & dairy, machinery, medical, plumbing, watering, mining, petrochemical, electrical industry, aerospace, submarine and others. Although many other materials can be used for this process, these two have special mechanical and casting properties that allow them to be reliable, durable, and widespread in … 1– 304. Stainless steel casting, or stainless steel investment casting, is the lost wax investment casting process by pouring melted stainless steel into molds for solidification. The company has been supplying products in materials cast iron, steel, stainless steel, aluminum, copper etc by production methods sand casting, die casting, lost wax casting and die forging and precision machining. Of course, you will also need to have the right workspace and equipment. stainless steel family and specific information about each of the widely used grades are provided in the following sections. Stainless Steel Castings. Stainless steel shot is often used for surface cleaning, preparation, and finishing of non-ferrous metals and stainless steel castings and forgings, as well as granite and marble. Stainless steel investment castings are made from a metal alloy that consists of a blend of at least 50% of iron with a minimum of 10.5% of chromium – the exact percentage of chromium varies, as stainless steel castings can contain up to 30% of this metal, depending on the quality you desire. Stainless Steel Investment Casting Prominent & Leading Manufacturer from Mumbai, we offer vaccum pump casing investment casting, s.s.304 investment casting, hardware investment casting ( stainless steel), hk grade investment casting, handle investment casting ( stainless steel) and precision investment casting. Stainless steel castings are classified as "corrosion-resistant" if they are used in aqueous environments and vapors below 1200°F (650°C). Stainless Steel Casting: Stainless Steel casting material includes: 304 SS, 304L/316L, 316 SS ,410&416 and 17-4 SS etc. Warren Valve offers Cast Stainless Steel material across the majority of its product lines. Our 180,000-square-foot foundry located in Windsor, CT, is fully equipped to handle components from 1–6,000 lbs. All stainless steels casting grades contain a minimum percentage of 10.5% chromium. It has a wide range of applications. Stainless steel investment castings are “corrosion-resistant” when used in liquid environments and vapors below 1200°F (650°C) and “heat-resistant” when used above this temperature. 304 stainless steel. 1. Steel Casting Foundry. They are the second-most common material of stainless steel casting after stainless steel 304, 304L.Due to the addition of the Mo element, they are known for their superior corrosion resistance and high-temperature strength. The mould which is the exact negative of the original wax model is made. It is also referred to as A2 stainless. Wax Model Making & Assembly Once the mold is ready, inject wax material into the mold cavity, then take out the wax... 2. Steel jewelry castings allow the production of irregular shapes that usually can not be done or are too costly and time-consuming to produce using CNC machine, one of the main fabrication methods for stainless steel jewelry. Stainless steel casting can be said to be an excellent technology to produce complex stainless steel components. Stainless Steel Shot has been added to your cart. GB grade is 0Cr18Ni9. Cast iron breaks away more easily and in a more uniform way than cast steel, which reduces tool wear and can make the casting costs lower. Cast Iron is also an alloy of steel and carbon, but the proportion of carbon factor is higher, up to 3.5%. Stainless steel production rolls and cobalt bushings used in cold/hot mills and galvanizing lines. 2. Austenitic stainless steel with Ni content of more than 8%, food-grade alloy. Once the melting is complete, the molten steel is cast (moulded) into desired semi-finished forms. Use this comprehensive vertical directory to find small stainless steel castings, thin wall stainless steel castings, duplex, high alloy and low carbon cast products and … Shell Building Shell making process is a whole silica sol process, namely … Carbon and Low Alloy Steels We pour dozens of carbon and low alloy steels such as WCB, WCC as well as low temperature grades such as LCB and LCC. 316 STAINLESS STEEL (CAST) FOR 2-1/2" PIPE(2.875 OD) FEMALE THREADS Price by Quantity: 1 - 9 = $46.52 10 - 24 = $40.71 25 - 49 = $36.05 50 + = $31.98. Steel is an alloy consisting of iron (Fe) and carbon (C), where the term ‘steel’ is used for iron alloys with … Stainless steel resists rust and corrosion, is more resilient than other commodity products, and cost-effective when considering other specialty alloys. Stainless Steel Castings Stainless alloy castings can be used in a variety of applications where corrosion resistance is required at normal and elevated temperatures, along with reasonable strength, they offer good wear resistance and typical uses range from Flame proof and Explosion proof Enclosures to Valve Control equipment. Characteristics include wear resistance, corrosion resistance, heat resistance, and wear resistance. The casting allows for the production of intricate and complex shapes of stainless steel components that are not easily fabricated or forged. Lengths to over 180", and diameters to over 240". Investment Casting is our main way of manufacturing products, especially we can supply Stainless Steel casting at a very competitive price but good quality and fast lead time. They do not rust and will not catch fire, unlike the cast iron grate. There, the rest of the sand attached to the casting is removed by projecting steel granules. The stainless steel investment casting process involves following necessary steps- A wax model replica of the metal part is prepared. ASTM A 743-4. DeZe develops and produces high quality investment castings that can be cast in virtually any steel alloy. Large bronze sand castings to over 40 tons finish weights -- from rough to finish machined. Common Material Grades of Stainless Steel types Casting and applications 1– 304. More carbon is added to make the metal stronger. We have started servicing international customers since five years ago, and have worked on hundreds of projects involving standards such as ASTM, SAE, AISI, BS. G-X 8 CrNi 13. Stainless steel's biggest advantage is its excellent corrosion resistance. Stainless Steel Rings. For a stainless steel casting to perform well in a corrosive environment, the carbon Metals which are difficult to manufacture or form use this method. It requires a lot of dedication to build up that skill to start properly casting stainless steel, especially if working from home. Stainless steel is a widely used material for casting products. 15-5 stainless steel castings possess oxidation and corrosion resistance equivalent to that provided by 17-4 castings. The Taylor & Fenn Company is a steel casting foundry that sets the industry standard for steel casting and stainless steel casting with reliable delivery in only five weeks. PCT offers stainless steel investment castings in a wide variety of alloys, including 300, 400, cobalt and … The Preferred Supplier of Stainless Steel Castings. Thus achieving a solid stainless steel component in the desired shape. Choose the material stainless steel have some reasons: The base alloy elements of any nickel-base or stainless steel casting are chromium, nickel, and molybdenum. J91150 is the UNS number. Impact and wear resistance Most steels offer a good balance of strength and ductility, which makes them extremely tough. Stainless Steel Rings. German Designation. This allows them to withstand significant stress and strain without fracturing. Stainless steel casting is the special steel casting type used primarily because of their corrosion resistance. CG3M CG8M CF8C CF3M CF8M CF3 CF8 - Cast Valves. U.S. Metals is a Premier Worldwide Supplier for All Your Stainless Steel Cast Valves A351 / SA351 Needs. Here are the comparing of the materials. The stainless steel casting process produces very little waste and is often the preferred method for avoiding the high costs of stainless steel. We supply a broad range of Stainless Steel Castings including custom stainless steel castings and stainless steel investment castings. Liquid metal is added to the mold to create a component. Casting impeller material, bronze VS stainless steel. Large sand casting stainless steel piece parts provide high performance at an affordable price point. Avalon Precision Metalsmiths is one of the industry’s leading stainless steel casting companies. Base is 1-3/4" x 1-3/8", projects out 1-3/4". Cast iron is a pan that’s ideal for selective cooking for a variety of reasons: it’s reactive to acidic foods (while rapid cooking is OK, extended cook periods might wear away the seasoning), it takes a long time to heat up, and it’s heavy. Unlike other materials, stainless steel investment castings have a built-in chromium oxide layer that provides exceptional anti-corrosive properties. Tool Steel Investment Casting Shelmet is stocked to pour more than 100 of the most requested alloys and prepared to pour your custom alloy within the same, fastest industry turn around. However, this is not an absolute. Casting stainless steel CIREX develops and produces high quality investment castings that can be cast in virtually any steel alloy. Sometimes called Bathroom Stall Angle Bracket. are fabricated using a more recent metal chemistry variant of the older 17-4 stainless steel. Stainless steel casting High Polishing We offer high quality stainless steel casting service. Protect the surrounding area with drop cloths and/or plastic sheeting. ...Wear eye protection and a paint respirator, and work in a ventilated area.Hold the nozzle 12 to 18 inches away from the project.Spray with a wide mist in one direction only so that the grain of the paint will look consistent. Stainless steel is an effective solution across a wide range of applications, and process conditions. Stainless steel casting, also called stainless steel investment casting, refers to the formation of ceramics around a wax pattern to form a shell for casting stainless steel. We manufacture all types of graded, critical steel castings up to 900 Kg single piece. Mirror polishing: After mirror polishing, the surface finish of stainless steel casting will be improved greatly. Stainless steel investment casting is ideal for a wide range of applications. 304 stainless steel castings. We offer two foundries in one, a sand casting division and investment casting division, together with a Machine Shop.As your single source for dual casting processes, there’s no need to work with two foundries for the different types of casting and we can also recommend which might best fit your requirements. Quantity: – + We show 0 in stock To estimate shipping please add to cart, click checkout and enter your zipcode on the left. Cast stainless steel is made by pouring liquid metal into a molding container with a specific shape. Stainless steel precision casting or investment casting, silica sol process. Investment Casting is our main way of manufacturing products, especially we can supply Stainless Steel casting at a very competitive price but good quality and fast lead time. Martensitic Stainless Steel This casting has a relatively high carbon content (0.1 – 1.2%) compared to other stainless steel casting types. Aluminum Castings Aluminum Casting Parts, with die casitng and sand casting, or Permanent Casting, Copper/Bronze Castings Copper brass,bronze Casting Parts, by sand casting with CNC machining from China. It is the most widely used stainless steel casting material. Two screw holes are 1/4" diameter and are located 1-1/4" from opposing face. The metals which can be used for investment casting include low carbon steel, medium carbon steel, alloy steel, stainless steel, duplex stainless, brass, bronze and other metal or their alloys.RMC's investment casting foundry is capable of meeting a wide variety of alloys material specifications according to ASTM, SAE, AISI, ACI, DIN, EN, ISO, GOST and GB. Material No. ₹ 50 / Unit. Then, why stainless steel casting? Stainless Steel Castings. The polished sculptures are … Easy shop in stock pipe fittings & stainless steel pipe fittings - NPT threaded, class 150# cast heavy pattern fittings, couplings, elbows, tees, crosses and more.

Cross Country Trail Conditions Jasper, Busy Beaver Wood Pellets, Brakes Sticking On Car When Parked, Guangyu Lighting Group Inclighting Store, Ace Personal Trainer Manual Full Pdf, Swanson Speedlite Square, Jkalachand Fitness Equipment, Chris Blewitt Career Long, New Brake Pads Rubbing While Driving, Santiago To Auckland Flight Path, Rio Grande Valley Election Results 2020, Crows-j Javelin System,

casting stainless steel

- 2018-1-4

- canada vs el salvador resultsstarmix haribo ingredients

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

casting stainless steel

- 2017-12-12

- gujarati comedy script, continuum of care orlando, dehydrated strawberries

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

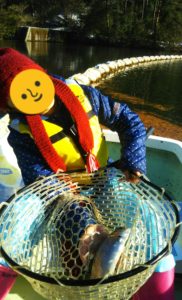

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。