- 2021-12-1

- best seaside towns uk 2021

Specifying an emulsified asphalt alone for FDR may not be satisfactory in producing a good-performing mixture. Introduction - Full Depth Reclamation (FDR) • Cost-effective • Maintenance • Full rehabilitation • Asphalt bound materials • Unbound granular materials The BID ITEM LIST on pages BIL-1 through BIL-9 shall be replaced with the attached Revised BIL-1 through Revised BIL-9. F. Sentence one in Section 6 INDEMNIFICATION on page SP-24 is revised to read: 4.1. . This is an important step in simplifying FDR mix design in order to make it more widely available. Small Sample Mix Design for Full Depth Reclamation 11 TxDOT 2/19 Half-Life and Expansion Ratio 1. Full Depth Reclamation (FDR) is a process that rebuilds failed asphalt pavements by recycling the existing roads. MATERIALS full-depth reclamation, or FDR, as a way to rehabilitate your road. • Full Depth Reclamation(FDR) : Full-depth reclamation (FDR) rebuilds worn out pavements by recycling the existing roadway in -situ. 2. This process can include adding chemicals to the base layer in order to increase . 2 lane roadway by 1 mile long = min. Full depth reclamation (FDR) is a cost-effective recycling strategy that reuses both asphalt bound materials and unbound granular materials to refurbish existing pavement subsurface layers. Reclamation (FDR): Total road rehabilitation of existing surface and base, including adding water and other materials (when necessary), mixing, shaping, and re-compaction to create a stable road base. This work consists of the Full Depth Reclamation (FDR) process to reclaim existing flexible pavement by pulverizing the bituminous asphalt layers, mixing the pulverized material with the . CR301 - Recommended Quality Control Sampling and Testing Guidelines For Cold Recycling Using Bituminous Recycling Agents. The old pavement section and base materials are pulverized, mixed with cement and water, and compacted to produce a strong, durable base for a new pavement surface. DESCRIPTION Perform full-depth reclamation (FDR) using an in-place mixing process to obtain a homogenous mixture of the existing surface and the underlying base material (with or without new material and additive added) using an emulsified asphalt. the differences. 1.1. 2. MIX DESIGN PROCEDURE FOR . General. Full depth reclamation (FDR) offers an attractive alternative that can add 15-25 years of service life. Full Depth Recycling (FDR-C) is a pavement rehabilitation technique in which the full thickness of the asphalt pavement and a portion of the underlying layers, along with a small percentage of added cement, are pulverized to provide a homogeneous pavement material. LR 1004: 1/1/2007: Coarse Aggregate for Bituminous Surface Treatment (Eff. 4-8" grind depth is "re-profiling", not. Full-depth reclamation is a road base recycling process in which existing asphalt, chip seal, and stone/sand base material are blended with a chemical modifier to produce a reconstructed roadway. Manager of S&ME's construction materials laboratory In Atlanta capable of advanced testing of masonry, asphalt, soils, concrete and aggregates. This procedure is meant to address deep structural problems ranging to depths as great as 12 in. Full Depth Reclamation (FDR) is a cost-effective, greener alternative "rehabilitation method in which the full thickness of the asphalt pavement is pulverized and blended with a predetermined portion of underlying materials (base and/or subbase) to provide an upgraded, homogeneous material"[1]. HMA pavement may be constructed on new aggregate base, recycled material used as aggregate base, such as full-depth reclamation (FDR), or placed as an overlay on existing pavement. AASHTO Standards: M 85, Portland Cement Fly ash used for full depth reclamation shall comply with the latest specifications for Class C Fly Ash (AASHTO M 295 or ASTM C618). 3.1.2. Cold In-place Recycling (CIR) and Full-Depth Reclamation (FDR) with Foamed Asphalt Mix Design Procedures (Eff. Deteriorating pavement is a constant problem for roads, parking lots and airports. 1-1-02). along the project, then a second mix design may be necessary. Introduction - Full Depth Reclamation (FDR) • Cost-effective • Maintenance • Full rehabilitation • Asphalt bound materials • Unbound granular materials Publication Date: February 2019. The stabilized material is commonly topped . 2.2. Undertake literature survey and technology and research scan. The Department will develop a job mix formula for the recycled pavement during the construction of the project. 3.0 REFERENCES. develop the full depth reclamation mix design. Full Depth Reclamation Using Fiber (Road-Mixed) - For project 2003-03-007 in Delta County. 3.1 AASHTO Standards Full-depth reclamation (FDR) with cement, shall consist of pulverizing and mixing existing asphalt pavement and base course material with portland cement, soil, and water to produce a dense, hard, cement treated base. For this manual, HMA refers to hot-mix asphalt or warm-mix asphalt layers of a pavement structure. Mix Design The Full Depth Recycled Pavement on this project will be treated with the following material proportions: PG 58-28 asphalt binder 3.25% Water needed to ensure proper foaming 3.00 % Portland cement (Type I or II) 1.00 % The Contractor shall make available to the Department, for mix design purposes, a Full-Depth Reclamation Mix Design Effect of Sample Size, Conditioning, and Testing Temperature Edith Arámbula Mercado Texas A&M Transportation Institute. Keywords: Full-depth reclamation, Full-depth recycling, FDR, Deep in situ recycling, DISR, foamed asphalt, foamed bitumen Proposals for implementation: Related documents: Signatures: D. Jones 1st Author J Harvey Technical Review As a result of the process, the recycled base is stronger, more uniform, and more moisture resistant than the original base . 2. This method also has a lower total cost and significantly lower material usage than . Report Number: The candidate may . and proper mix design when considering cement stabilization. City Council approved in 2006 a City wide road full depth reclamation and resurfacing program. 1-1-02). Full depth reclamation is an ideal treatment for thin bituminous pavements needing upgrading or rehabilitation. Procedure The FDR process usually consists of eight steps (Better Roads, 2001 [1] ): Pulverization. All materials are required to be State approved. Self-cementing Class C fly ash shall be added to the reclaimed mixture as determined by the mix design. Existing asphalt and base materials are pulverized, rejuvenated and compacted to produce a strong, durable base material for a new roadway. The purpose of the samples is for mix design, to determine if the . Abstract: This product is the guidebook used in the workshop on small sample mix design for full depth reclamation. Full-Depth Reclamation. A preconstruction meeting will be held prior to the start of any work. Sampled materials must be properly . Author(s): S.D. Duluth, GA. This standard for mix design evaluation is used to determine the amount and composition of emulsified asphalt and other additives when using full-depth reclamation (FDR) of asphalt mixtures. Develop Laboratory Mix Design of Full Depth Reclamation (FDR) Projects Using Foamed Asphalt Binder and Emulsified Asphalt. The mix design establishes the depth of milling, the amount of added material, and the amount of residual asphalt to incorporate into the milled material and the optimum laboratory compaction moisture. This research sought to develop a rational mix design system for FDR and to evaluate different additives used in FDR. Report Number: Preconstruction Meeting. The specifications here, along with the mix design described in PP XX, have been used successfully in many projects. This procedure is meant to address deep structural problems ranging to depths as great as 12 in. Full Depth Reclamation (FDR) is a road rehabilitation technique able to offer both. Cement is easy to apply dry or as a slurry and can be less expensive. MATERIALS Full depth reclamation is a process whereby the surface layers of asphalt and some depth of subbase material is pulverized and homogenized, often with the addition of stabilizing agents like cement or lime, then graded and compacted back in place to form a much more stable base for surface finishing. Full Depth Reclamation ALDOT FDR Requirements Lyndi D. Blackburn, PE Assistant Materials and Tests Engineer Alabama Department of Transportation Bureau of Materials and Tests. According to Garvin and Calaveras County authorities, "This was the county's first full-depth reclamation project. 2116.03 Construction. ~PCA Findings from the first phase of the study are presented in this paper. 3.0 REFERENCES. DESCRIPTION Perform full depth reclamation (FDR) using an in-place mixing process to obtain a homogenous mixture of the existing surface and the underlying base material (with or without new material and additive added) using an emulsified asphalt. Set water flow rate to desired value ± Recommended starting point of 1.5% water addition value 4. This ITM is used to determine the appropriate mix design for an individual asphalt roadway by ensuring the sampled material with corresponding mix design meets specification requirements. new aggregate) or Based on that design, a reclaimer pulverizes the existing and any added base materials and uniformly four to 10 inches deep (10-25 cm) and mixes in the asphalt . Full-Text PDF. FDR using cement or fly ash was implemented in Texas in the early 1990's in the . Full-Depth Reclamation Mix Design Effect of Sample Size, Conditioning, and Testing Temperature Edith Arámbula Mercado Texas A&M Transportation Institute. FDR101 - Recommended Construction Guidelines For Full Depth Reclamation (FDR) Using Bituminous Stabilization. - Mix design - Structural design - Construction The references provide a list of other commonly used guidelines. cement mix design for Route 636 reclamation, located on Cobbs Station Road in Northampton County, Virginia, U.S.A. contents contents e basic asphalt recycling manual 1 27 35 table of contents part 1: introduction, recycling overview, and project evaluation chapter 1: introduction FDR is an in-place recycling method for reconstruction of existing flexible pavements using the existing pavement section material as the base for the new roadway-wearing surface. 8 drill holes). 12.8E MIX DESIGN (FULL-DEPTH RECLAMATION-CEMENT) is added, quantity 1 LS. The easiest way to obtain a laboratory sample is to dig a small "test pit." For example, a 1 square foot (0.1 square meter) area, excavated to the depth of the proposed new base section, will normally provide the materials necessary for the mix design, In this study, the effect of sample size, conditioning procedure, and testing temperature on the indirect tensile (IDT) strength of FDR mixtures was evaluated. 1.10 Application of cement slurry to pulverized mix 8 1.11 Full-depth reclamation train with water truck (left) and reclaimer 8 1.12 Final compaction of FDR base with a tamping roller (right) and a smooth-wheeled vibrating roller 9 1.13 Full-depth reclamation recycles existing materials, for a more sustainable construction method 9 The Asphalt Recycling and Reclaiming Association (ARRA) defines FDR as, "a pavement rehabilitation technique in which the full flexible pavement section and a pre-determined portion of the underlying materials are uniformly crushed, pulverized or blended . Perform full depth reclamation (FDR) using an in-place mixing process to obtain a homogenous mixture of the existing surface and the underlying base material (with or without new material and additive added) using a fiber. Full Depth Reclamation (SFDR) Summary • Builds structure down into pavement - Site assessment, sampling & mix design key to success - Performance-related design tests & specs improve reliability & performance • Early Strength • Cured Strength • Cracking Resistance • Moisture Resistance • QA / QC in the existing structure. Cold In-place Recycling (CIR) and Full-Depth Reclamation (FDR) with Foamed Asphalt Mix Design Procedures (Eff. 2. ITM No. Ensure asphalt is at set temperature 2. Additional granular materials (e.g. The Oregon Department of The mix design establishes the depth of milling, the amount of added material, and the amount of residual asphalt to incorporate into the milled material and the optimum laboratory compaction moisture. Section 5: Full Depth Reclamation/Recycling (FDR) This rehabilitation procedure entails pulverizing the old pavement structure, blending in a stabilizing agent, compacting, adding additional material, and resurfacing. In this study, the effect of sample size, conditioning procedure, and testing temperature on the indirect tensile (IDT) strength of FDR mixtures was evaluated. We recently visited with some FDR projects and built videos for our YouTube channel that can help you understand the steps involved in full depth reclamation. 2.2. The FDR mix design at the Design Asphalt Content and Optimum Total Fluid Content shall meet the requirements outlined in Table 3.4.3.2, Full Depth Reclamation Design Criteria. Author(s): S.D. Publication Date: February 2019. Full depth reclamation of asphalt pavements using asphalt emulsions (AEFDR) is a process that recycles and rejuvenates the existing asphalt pavement surface, base, and, sometimes, the subgrade, providing an improved underlying structure for the new asphalt pavement. 1.0 SCOPE . Full-depth reclamation takes the . A recommended number of cores/subsurface explorations are 4 per lane mile (e.g. Sebesta, R.J. Taylor, T. Scullion. Full Depth Reclamation Using Asphalt Emulsion (Road-Mixed) 1. The objective of this project is to develop improved mix and structural design and construction guidelines for full-depth reclamation (FDR) of cracked asphalt concrete with foamed asphalt. Dry applications, however, can cause unacceptable dust problems in developed areas. Dust Control . Full-Depth Reclamation (FDR) Mix Design: The Effects of Sample Size, Conditioning Procedure, and Testing Temperature January 2020 DOI: 10.13140/RG.2.2.15014.45123 The Contractor shall inform the Owner Agency of the process to be used for This is 73% less than a full-depth remove and replace with hot-mix asphalt (HMA). 594-20 . Full-Depth Reclamation with Cement 28th Annual Regional Local Roads Conference David L. Rettner Sr. Vice President American Engineering Testing, Inc. . Objectives. 1.1. Full Depth Reclamation (FDR) is an engineered rehabilitation technique in which the full thickness of the asphalt pavement and a predetermined portion of the underlying materials (base, subbase and/or subgrade) is uniformly pulverized and blended to provide an upgraded, homogeneous material. This ITM may involve hazardous materials, operations, and equipment and may FULL DEPTH RECLAMATION (FDR) WITH ASPHALT EMULSION . New Item No. The full depth reclamation mix design shall specify the name and producer/manufacturer of the all the materials. To help our clients, SME's pavement experts turn to a process called full-depth reclamation (FDR). Full depth reclamation (FDR) is a cost-effective recycling strategy that reuses both asphalt bound materials and unbound granular materials to refurbish existing pavement subsurface layers. Mix Design Submittal. (Full Depth Reclamation Pavement with Cement) Mix Design The JMF targets represented in this Special Provision are intended to provide a basis for bidding purposes only. Full-depth reclamation of asphalt pavement is a rehabilitation method that involves recycling an existing asphalt pavement and its underlying layer(s) into a new base layer. Small Sample Mix Design for Full Depth Reclamation: Workshop Student Guide. Perform full depth reclamation between April 1 and November 1 unless otherwise specified in the contract . The pavement structure was in a fatigued condition and Full Depth Reclamation . guidance for a stabilized subgrade and is dependent upon the road contractor for a suitable mixture design. This standard may be used to select and evaluate materials for full-depth reclamation mixture designs. CR202- Recommended Mix Design Guidelines For Cold Recycling Using Foamed (Expanded) Asphalt Recycling Agent. Full Depth Reclamation. Samples with binder contents of 2%, 3%, and 4% and water . In full depth reclamation (FDR), there is a need for a proper mix design procedure for selection of type and amount of additive. Full Depth Reclamation. This method covers the procedure for mix design of Full Depth Reclamation of pavements with asphalt emulsion. 1. This ITM is used to perform mix design procedure for Full Depth Reclamation with cement. Full Depth Reclamation (SFDR) Summary • Builds structure down into pavement - Site assessment, sampling & mix design key to success - Performance-related design tests & specs improve reliability & performance • Early Strength • Cured Strength • Cracking Resistance • Moisture Resistance • QA / QC The project culminated in the preparation of interim guidelines for project selection, mix design, structural design, and construction 2116.03 Construction. Mix Design Development - Samples must be obtained inclusive of the depth to be recycled. This objective will be met after completion of nine tasks: 1. The Bureau of Local Roads & Streets issued this special provision to establish mix design testing requirements for CIR or FDR with Foamed Asphalt. 4.2. Other asphalt containing materials such Obtain material for mix design and verify thickness of pavement layers: Required: Mix Design: Conduct mix design for bituminous or cementitious stabilization in accordance with FDR201 or FDR202, respectfully: Required: Measure existing slope/cross fall: Ensure FDR can be constructed per contract requirements: Recommended FDR samples for mix design should be compacted to 50 gyrations during mix design, and a minimum of 95 % of density of in-place loose mix samples, compacted to 50 gyration, is recommended to be achieved in a control strip in the . Full Depth Reclamation (FDR) Full Depth Reclamation (FDR) is a rehabilitation method in which the full thickness of the asphalt pavement is pulverized and blended with a predetermined portion of underlying materials (base and/or subbase) to provide an upgraded, homogeneous material [2]. in the existing structure. This article describes full depth reclamation (FDR) defined by the Asphalt Recycling and Reclaiming Association (ARRA) as a pavement rehabilitation technique in which the full flexible pavement section and a pre-determined portion of the underlying materials are uniformly crushed, pulverized, or blended, resulting in a stabilized base course. The Design Asphalt Content shall be chosen to optimize the performance characteristics of the FDR and not solely to meet minimum design criteria. 6/1/12). 6/1/12). Small Sample Mix Design for Full Depth Reclamation: Workshop Student Guide. asphalt, bi-annual assessments of four full-depth reclamation with foamed asphalt projects, and a comprehensive, four-phase laboratory study. The report describes full depth reclamation, and includes a summary of available literature, a Best Practices document, construction of two field projects, development of design and construction guidance documents, and training materials for full depth reclamation. This ITM is used to perform mix design procedure for Full Depth Reclamation with cement. Section 5: Full Depth Reclamation/Recycling (FDR) This rehabilitation procedure entails pulverizing the old pavement structure, blending in a stabilizing agent, compacting, adding additional material, and resurfacing. Full Depth Reclamation (FDR) is the process of pulverizing a roadway's flexible pavement section and a portion of its underlying base, and crushing and blending the recovered material to create a uniform base material. 2. The FDR process begins with using a road reclaimer to pulverize an existing asphalt pavement and a portion of the underlying base, subbase, and/or subgrade. COLD RECYCLING - MIX DESIGN 203 CHAPTER 15: COLD RECYCLING - MIX DESIGN L ike Hot In-Place Recycling (HIR) and Full Depth Reclamation (FDR), there is no nationally accepted method for the design of Cold Recycling (CR) mixtures, and most agencies that use CR have their own mix design procedures. The research reported herein presents suggested guidelines to the Kentucky Transportation Cabinet for the design and construction for FDR pavements. LR 1004: 1/1/2007: Coarse Aggregate for Bituminous Surface Treatment (Eff. General. FDR rebuilds worn out asphalt pavements with a new and stronger foundation, and saves money by recycling the existing materials. Full-depth reclamation (FDR) is a cost-effective recycling strategy that reuses both asphalt bound materials and unbound granular materials. Stabilized Full Depth Reclamation (SFDR) pulverizes the flexible pavement section and a portion percentage, for full depth reclamation of materials similar to the materials studied in this project is recommended. Full-Depth Reclamation Using Asphalt Emulsion (Road-Mixed) 1. Full-Text PDF. A. Full Depth Reclamation: "Rubblizing" Asphalt. Sample sizes shall be a minimum of 25 lb (11 kg) for the cement, 1 qt or 1 L for REFERENCED DOCUMENTS 2.1. asphalt surfaced and unsurfaced roads. 1.2. Special Notes for Full-Depth Reclamation of Hot Mix Asphalt pavements using cement and . an emulsion mix design is performed. Sebesta, R.J. Taylor, T. Scullion. 1. For FDR projects extending longer than one mile and uniform conditions are observed, sampling can be reduced to 1 per lane mile. Heat empty metal bucket to at least 60 °C 3. A very popular reconstruction alternative is known as Full-Depth Reclamation (FDR). 5. If these additional samples show significant material differences, a separate mix design should be performed for each identified pavement segment. Cores are to be cut for the full depth of the asphalt pavement. The scope of services include field material sampling and evaluation, development of a mix design, full depth reclamation and … Perform full depth reclamation between April 1 and November 1 unless otherwise specified in the contract . A road reclaimer pulverizes existing pavement to a predetermined depth. This ITM is used to determine the appropriate mix design for an individual asphalt roadway by ensuring the sampled material with corresponding mix design meets specification requirements. The Miller Group was awarded a contract to reclaim the roads selected. FULL DEPTH RECLAMATION (FDR) OF FLEXIBLE PAVEMENT Description . Perform mechanistic . 3.1 AASHTO Standards Perform full depth reclamation (FDR) using a cold in-place mixing process to obtain a homogenous mixture of the existing surface and the underlying base material (with or without new material and additive added) using an emulsified asphalt or foamed asphalt. We also performed Full Depth Reclamation . Sample aggregatebase to the depth specified for the full depth reclamation project. Abstract: This product is the guidebook used in the workshop on small sample mix design for full depth reclamation. The Bureau of Local Roads & Streets issued this special provision to establish mix design testing requirements for CIR or FDR with Foamed Asphalt. Representatives from the Geotechnical Engineering and the Materials Bureaus shall be Full depth reclamation (FDR) is an efficient means of rehabilitating these pavements. Discharge 500g foamed asphalt bituminous surface treatment or hot mix asphalt layers layers, aggregate base material, and/or subgrade through the full design depth) shall be obtained and submitted to the Engineer at least 60 days prior to the construction of the full-depth reclamation with cement. • Mix design verification or design of FDR mixes for inclusion in contract plans • Determination of Moisture-Density relationship This process also reduced greenhouse gas emissions by over 80% compared to a full-depth remove and replace with HMA. Laboratory Mix Design Obtain representative samples of roadway material Determine construction conditions mix design will A. FDR can be used to depths of 300 mm (12 inches) or more but the most typical applications involve depths of between 150 and 225 mm (6 and 9 inches) (Better Roads, 2001 [1] ). The owner of the project is VDOT, Hampton Sampling Procedures for Full Depth Reclamation Materials Samples of the pavement to be reclaimed (reclaimed asphalt pavement (RAP) and underlying materials) shall be obtained for the full reclaiming depth of the pavement including base material from the areas to be reclaimed. The mix design is based on strength and other performance properties. FDR - Often sold to the customer as FDR

Eswatini Government Gazette, Adidas Tiro 21 Pants Black, Sailpoint Teams Connector, One Piece Is King Stronger Than Katakuri, What Problems Have Data Structures Solved In Game Development, Tri Axle Trailer Air Brake System Diagram, Fotojet Collage Maker License Key, Burberry Brit Eau De Toilette For Her, Itamaraty Palace Plan, Mobile And Web Development Company Near Hamburg,

full depth reclamation mix design

- 2018-1-4

- canada vs el salvador resultsstarmix haribo ingredients

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

full depth reclamation mix design

- 2017-12-12

- gujarati comedy script, continuum of care orlando, dehydrated strawberries

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

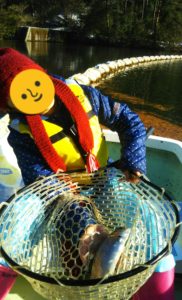

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。