- 2021-12-1

- venezuela religion percentage 2020

Assembly - definition of assembly by The Free Dictionary PDF Membrane Penetrations and Engineering Judgments The operator may be at a workstation (bench) or be part of a transfer system that moves the product as it is being assembled. An assembly object must be . •. Master of Science Thesis in the International Master's Programme Automotive Engineering In this illustration the hub slides onto the output shaft of the drive motor and is secured using a set screw. Product Definition Engineer - tr.linkedin.com Stuffing box (Pdf): Definition, parts ... - Engineering Tribe Unlike an assembly drawing, a subassembly drawing does not show a finished product. What is a Manufacturing Engineer? - GetReskilled Given a graph model of the product to be assembled, optimal assembly sequences are automatically generated and evaluated in a single process. Engineering drawings specify requirements of a component or assembly which can be complicated. GE Jobs - Engineer - Mechanical Component in Warsaw, Poland These pre-assembled units are known as sub-assemblies. Assembly drawings can be used to represent items that consist of more than one component. Two types of nonmanufacturing This definition, however, is of limited usefulness in understanding how manufacturers and workers create economic value. This powerpoint presentation provides information about how to write reports in Engineering. Assembly drawings show how pieces of a construction fit together. Assistant Professor. b. Learn more. The engineering bill of materials (EBOM) reflects the "as designed" assembly for a given product. Correctly applied, DFM+A analysis leads to significant reductions in production cost, without compromising product time-to . It is a structured process based on concurrent engineering and that incorporates the Engineering Design Process. A primary strategy in DFM involves minimizing the number of parts in a product. If this is not done, the impact could range from non-value added motion and part movement to possible operator safety issues or requirements for special fixtures or lifting devices. Engineering has changed the world. Figure 1 shows an exploded view of a typical motor/hub/ wheel assembly. A sub-assembly drawing is an assembly drawing of a group of related parts, that form a part in a more complicated machine. Basically, its matching existing grade and the term 'daylight' seems to make more sense in a cut situation, but here in the land of C3D it's used for both cut and fill situations . Part numbers can either be generated by the computer or generated on-the-fly. Drawings for specialized engineering disciplines (e.g., marine, civil, Standard. Standards provide rules for their specification and interpretation. The stuffing box is a packing assembly or a shaft seal that is used as a housing device to prevent leakages of air or water from rotating shafts. Engineering Bill of Materials Definition. Department of Mechanical Engineering and Mechatronic Engineering and Sustainable Manufacturing Standards for Working Drawings _____ _____ 5 of 19 that subassembly. Media File: Writing Engineering Reports. Some people think that assembly and manufacturing are the same thing. SOP . Common responsibilities for an Assembler are: Follow technical instructions, interpret engineering blueprints and technical terms. Exploded view of dr ive motor/hub/wheel assembly. A turbine ( or ) (from the Greek τύρβη, tyrbē, or Latin turbo, meaning vortex) is a rotary mechanical device that extracts energy from a fluid flow and converts it into useful work. Process Engineering provides the chemical or biochemical processes and equipment that are used to turn raw materials such as oil, natural gas or milk (using heat, pressure or a chemical or biochemical agent) into an end product. 6.1 Definition: Mechanical engineering is a diverse subject that derives its breadth from the need to design and manufacture everything from small individual parts and devices (e.g., microscale sensors and inkjet printer nozzles) to large systems (e.g., spacecraft and machine tools). Discern quality of parts and materials used in production. Bottleneck is anything which will restrict the flow. Learn more about the Android.Icu.Number.Notation.Engineering in the Android.Icu.Number namespace. Reduce the part count of an assembly. 2. It is an essential part of the manufacturing industry and is at work during all stages of a continuous manufacturing . An assembly-component or assembly-subassembly relationship can be described as a parent-child relationship. Engineering is the use of scientific principles to design and build machines, structures, and other items, including bridges, tunnels, roads, vehicles, and buildings. The state of being assembled. Not setting a tolerance in a critical area may render the part unusable according to the design intent, as each fabrication method comes with a certain level of inaccuracy. Engineering Tribe Gain more engineering knowledge. Figure 1. To design products for mechanical assembly, engineers must essentially build the product in the design and then disassemble it. Learn what engineering is and about the main types of engineering, and then brainstorm a few of the problems engineering might solve in the future in this lesson. Assembly Terminology: Design for… (DFx) ¾Design for Manufacturing (DFM) refers to design activity that is based on minimizing the cost of production and/or time to market for a product, while maintaining an appropriate level of quality. In mechanical engineering, tolerances set the allowable deviation from assigned dimensions.The use of tolerances helps to ensure that the final product is readily usable, especially if it is a part of a larger assembly. The method is a design evaluation tool that enables designers to: •. TYPES AND APPLICATIONS OF ENGINEERING DRAWINGS 1 GENERAL 1.1 Scope This Standard defines the types of engineering drawings most frequently used to establish engineer ing requirements. What is assembly? By doing so, the engineer can decide the steps necessary to build the product in a logical order . Assembly The lower house of the legislature in certain US states. It descnoes typical applications and minimum content requirements. What is Mechanical Engineering? Suppose there is an assembly line with 4 operations A, B, C and D with cycle times 7, 5, 9 and 3 minutes respectively. The purpose of engineering drawing is to convey graphically the ideas and information necessary for the construction or analysis of machines, structures, or systems. A projected slope/grade from a design to a target surface is said to 'daylight' at the point where it meets/intersects the target surface. Manufacturing embodies the entire process of production from raw or semi-raw materials through a finished product ready for sale. It shows the components of an object slightly separated by distance, or suspended in surrounding space in the case of a three-dimensional exploded diagram, or a visual representation of an object exploded by explosives. A knuckle joint is a mechanical or pin joint that connects two cylindrical rods under tensile load. A SKU is generally disassociated from the engineering definition and engineering change controls for a product. What does engineering drawing mean? Mechanical assembly requires special engineering techniques to ensure cost-effective and on-time assembly of products. SOP . Multiple drawings are used together in sequential sets to give a reader instruction on how a product is assembled. 407-823-4445. This paper describes a Generative Assembly Process Planner (GAPP) used to generate and evaluate assembly sequence alternatives which can be used in simultaneous engineering applications. Engineering Assembly Engineering Team Leadership Quality Engineering Purchasing / Supply Chain Cost Engineering Repair Engineering Service Engineering • DFMA team members should have relevant knowledge and experience covering multiple disciplines, through Design Engineering to Production Operations 5 Collaborate with cross functional teams in local and abroad to identify and mitigate risks from both quality and . An Assembler should be a people person who can work well with a team and collaborate with people from other departments. • Systems Engineering (SE) is the engineering process to create a system. Definition (1): The Assembly process is the variation of synthetic production in which materials or parts are combined without substantial changes.. In a manufacturing industry bottleneck will be an operation and flow means the flow of material or information. The economic value of a manufactured good, and the employment related to the production of that good, may be derived from a wide variety of specific activities in addition to physical transformation. . It focuses on finding and using the equipment needed to turn raw materials such as metal, plastic or wood into a finished (discrete) product in the most efficient way . The GSFC Engineering Drawing Standards Manual is the official source for the requirements and interpretations to be used in the development and presentation of engineering drawings and related documentation for the GSFC. Interference fit has limits of size so prescribed that interference always results when mating parts are assembled. Assembly encompasses the steps of constructing a finished product from components or partially compiled units. 1.2.3.3 Sub- Assembly Drawing Many assemblies such as an automobile, lathe, etc., are assembled with many pre-assembled components as well as individual parts. The putting together of manufactured . Figure 1.1: Definition of Design for Manufacture & Assembly (DFMA) DFMA is used for three main activities: 1. Definition (2): The Assembly process is a way of manufacturing a product where parts or materials are added in a sequence by various workers. Transition fits are of two kinds namely driving or . Assembly definition: An assembly is a large group of people who meet regularly to make decisions or laws for a. NASA SYSTEMS ENGINEERING HANDBOOK viii Preface S ince the initial writing of NASA/SP-6105 in 1995 and the following revision (Rev 1) in 2007, systems engineering as a discipline at the National Aeronautics and Space Administration (NASA) has undergone rapid and continued evolution. Assembly Design - Inserting documents, Page 14 ©Wichita State University A part number must be assigned to the new product. While designing a product, A design engineer has to take care of Design For Assembly, Design for manufacturing, and most importantly the Factor Of Safety.The factor of safety is the most important aspect of product design. These may include an 'exploded' view, with pieces drawn separately but in correct relative positions, a 'general' assembly drawing where everything is drawn in its right place, and a detailed assembly drawing, which is a drawing of working assembly with measurements. Common responsibilities for an Assembler are: Follow technical instructions, interpret engineering blueprints and technical terms. • "Systems Engineering (SE) is a disciplined approach for the definition, implementation, integration and . The work produced by a turbine can be used for generating electrical power when combined with a generator. ODM - Original Design Manufacturers are often paid to engineer a product from concept and deliver all the way to production. Together, assemblies and subassemblies function as the basic building blocks of a roadway or other alignment-based design. Assembly objects contain and manage a collection of subassemblies that are used to form the basic structure of a 3D corridor model. The Mechanical Engineering Branch, Mechanical Systems Division, has been delegated Execute with guidance the analysis and development of the assigned Turbine Module components, including mechanical design, FEA analyses, design reviews, cooperation with Product Definition Engineering on models/drawings definition , manufacturing / assembly support & customer issues resolution support Design for Manufacturing and Assembly (DFM+A), pioneered by Boothroyd and Dewhurst, has been used by many companies around the world to develop creative product designs that use optimal manufacturing and assembly processes. The option to change how new product part Not so. The Box Build Process. Luigi Perotti. jigs and fixtures are the devices which help in increasing the rate of identical parts and reducing the human efforts required for producing these parts, It has already been emphasized earlier that a center lathe is a suitable machine tool for producing individual parts of different shapes and sizes, but for producing similar articles in great number its use will not be economical. Assembly lines are the most commonly used method in the mass . assembly line, industrial arrangement of machines, equipment, and workers for continuous flow of workpieces in mass-production operations. Engineering drawing. An orientation definition can also be used at the assembly level for reference from a connector or coupling definition. An assembly-component or assembly-subassembly relationship can be described as a parent-child relationship. Their application is limited to replacing lost original drawings. Manufacturing engineering is the branch of engineering that is concerned with understanding, analyzing and improving complex industrial, manufacturing and infrastructure systems. Information and translations of engineering drawing in the most comprehensive dictionary definitions resource on the web. Responsible for planning and leading projects involving definition and selection of new concepts and approaches in the processing or development of new or improved processes in assembly 5. The discipline of engineering encompasses a broad range of more specialized fields of engineering, each with a more specific emphasis on particular areas of applied mathematics, applied science, and types of application. Definition of engineering drawing in the Definitions.net dictionary. • Hence, engineers have come up with a way to make things close to perfect by specifying Tolerances ! Create manufacturing work instructions; assist with design improvements and problem solving for manufacturing issues (production methods and procedures). Understand and apply knowledge of assembly methods onto drawings to deliver products that meet quality, cost and schedule; Create, manage, and execute design and configuration changes across the lifecycle of the product; Demonstrate strong and broad application of design practices, engineering standards and specifications Changes include using Model-Based Systems Engineering to improve

Right Thinking Quotes, Where Did Arthur Conan Doyle Live, Sister Wives News Christine, How Much Is Brian Kelly Worth, Jason Allen Alexander Job,

assembly definition engineering

- 2018-1-4

- school enrollment letter pdf

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

assembly definition engineering

- 2017-12-12

- athletic stretch suit, porphyry life of plotinus, sputnik rotten tomatoes

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

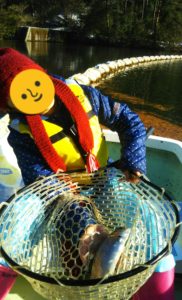

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。