- 2021-12-1

- platinum performance equine

The DIE BONDING PROCESS FOR MANUFACTURING SEMICONDUCTOR DEVICE AND SEMICONDUCTOR DEVICE MANUFACTURED THEREBY patent was assigned a Application Number # 16816108 - by the United States Patent and Trademark Office (USPTO). Hydroentanglement is a mechanical bonding process designed to produce nonwoven fabrics with texture and appearance that resemble woven and knitted fabrics. Cold Cu . The cast-bonding process enables steel components of a wide range of geometries to be protected with heavy overlays of, for example, alloy white cast iron or cobalt-base material. Have an extensive grasp on the fundamentals of semiconductor bonding process and leverage this to explain downstream impacts and recommend process improvements from first principles Outer layers must join with the substrate. post curing. Cold solder FC Process-. A unit of gold bonding wire-1 . Kulicke and Soffa 3.8. Along with welding and soldering, adhesive bonding is one of the basic joining processes.In this technique, components are bonded together using adhesives.The broad range of types of adhesives available allows numerous materials to be bonded together in products as diverse as vehicles . Our equipment experts are ready to advise engineers on the best solution to meet their process needs. H.B. This includes machinery for balloon forming, balloon bonding, balloon folding, necking, cutting, coating, testing, mold production and more. The processes, namely, brazing, soldering, and adhesive bonding are grouped under solid / liquid state welding. Heat is generated during the manufacturing process either by a heated capillary feeding the wire This situation has changed dramatically. When integrating bonding technolo-gy into a manufacturing process, an optimum result is only achieved if all parts of the total system are har-monized with each other to the best possible degree. However, many void defects exist between layers in the printing process of additive manufacturing; consequently, the bonding performance between layers is poor. The bonding is usually chemical bonding, but sometimes mechanical bonding is integrated with the chemical bonding. Typical products include internally-clad pipe bends and fittings, composite valve seats and composite billet shear blades. Diffusion bonding is a solid state joining process first developed for commercial use in heat exchanger manufacture by Heatric in the early 1980s. Identifying Adhesive Bond Failure Points in Manufacturing. Ultrasonic additive manufacturing (UAM) is an additive manufacturing technolo-gy that combines an additive process of joining thin metal foils layer by layer using ultra-sound and a subtractive process of CNC contour milling. Cure-on-demand high-precision process is highly welcome in manufacturing and allows for exclusion of non-cured adhesives from bonded substrates and parts. A bonding process with Carding is a mechanical process which starts from bales of fibres. The polarizing plate attachment is attached in its precise position on the outer surface of the panel. A packaging process, which is a back-end process for manufacturing semiconductors, proceeds in the order of back grinding, dicing, die bonding, wire bonding, and molding. The primary material is called Substrate, and a secondary material is called Subsequent. Staff Process Engineer Wire Bonding. The elimination of solder enables smaller bonding pitches and smaller interconnect sizes. Adhesive bonding is a joining technique used in the manufacture and repair of a wide range of products. Adhesive application. ENEPIG (Electroless Nickel, Immersion Palladium, Immersion Gold PCB) was derived out of the need to combat the challenge with the immersion gold process and Black Pad Syndrome. This process allows for the creation of compact heat exchangers with exceptionally high performance. Overmolding is a plastic manufacturing process where two materials ( Plastic or Metal) are bonded together. Patent Application Number is a unique ID to identify the DIE BONDING PROCESS FOR MANUFACTURING SEMICONDUCTOR DEVICE AND SEMICONDUCTOR DEVICE MANUFACTURED THEREBY mark in USPTO. 1. Machine Solutions is proud to be the one-stop shop for all balloon catheter manufacturing processes. The adhesive, however, must bind to the surfaces on which it's applied. The additive manufacturing of continuous fiber composites has the advantage of a high-precision and efficient forming process, which can realize the lightweight and integrated manufacturing of complex structures. These methods include selecting the log, debarking, cutting the logs, peeling the log, making a continuous ribbon of wood, cutting and stacking, gluing the wood, pressing the wood, trimming, sanding, and finishing. molding. As a result, we manufacture components, subassemblies, and complete products for mission-critical aerospace, semiconductor, as well as medical applications. Fort Washington, PA 19034. Manufacturers inspect semiconductor wire bonding for flaws such as disconnected wires, shifts in wire pitch, bonding separation, or peeling and migration. More than 90% of the chip interconnections produced annually This is a service that IFAM offers to its customers. Bonding is an important process used in all fields of industry, where the tight joining of two materials is required. The bonding process can be thought of as four steps: 1. Performs analyses and selects techniques to solve problems and enhance product yield and process flows. Wire-bonding is an ultrasonic, metal- metal friction welding process that is used to connect cells into a battery pack. Job is located in beautiful Newburyport, Massachusetts - Relocation assistance offered. Parts are designed using traditional 3D- CAD modeling programs, then divided into 2 layer sections that equal the thickness of each sheet of metal. This process makes near-net-shape forming of components possible from presized multisheets of titanium, enabling significant weight and cost savings. laser marking, and. The objective of this article is to present microstructural evidence of a bonding mechanism between copper, which has been deposited by the cold spray process, and an aluminum substrate. Flux dipping & mass reflow-. Adhesive Bonding is the process of joining two surfaces together, usually with the creation of a smooth bond. The technology is not new per se and has been widely utilized in microelectronics and power electronics industries since the 1970. Ball bonding is generally used in thermocompression (T/C) or thermosonic bonding (T/S) process. Diffusion Bonding is a solid-state joining process which is applicable to similar and dissimilar materials, primarily metals, although ceramic materials can also be joined using this process. The process starts with picking a die from a wafer or waffle pack and then placing it at a specific location on the substrate. When integrating bonding technolo-gy into a manufacturing process, an optimum result is only achieved if all parts of the total system are har-monized with each other to the best possible degree. ENEPIG Benefits for Gold Wire Bonding | PCB manufacturing process. Diffusion Bonding Diffusion Bonding is a solid-state joining process which is applicable to similar and dissimilar materials, primarily metals, although ceramic materials can also be joined using this process. It includes a wide variety of processing technologies that can be placed in a. In the first stage, the surfaces to be welded are drawn together by normal compression of the sonotrode. As a general trend, however, the enhanced bonding characteristics and performance of a new generation of adhesives is helping to reduce the number of parts typically used in a finished product. The spunbond process is a nonwoven manufacturing system which combines the spinning process with the sheet formation process by placing the bonding device in the same continuous line (Dahiya, Kamath, & Hegde, 2004). While glue is commonly used for this process, epoxy or other types of adhesives may be used as well. Grinding: This process improves the performance of the brake shoe and also improves its look. With the layers ready and confirmed, they simply need to fuse together. This process is applied to a commercially pure aluminum up to four . The process involves applying high temperature, and pressure to metals mated together in a hot press causes the atoms on solid metallic surfaces to intersperse and bond. Depending on the materials selected for the substrate and overmold, materials may be bonded chemically or mechanically (via undercuts, for example). Nonwoven manufacturing can be described in simple terms as a series of manufacturing steps consisting of forming a fibrous web, entangling or bonding the fibres in the web to impart mechanical integrity to the structure and finishing/converting the fabric to impart some special properties to the fabric that the . Today the diffusion bonding process is being used for a new additive technology called Laminated object manufacturing (LOM). The hybrid bonding is well established at wafer level and a very promising technology for fine pitch stacking with through-silicon-via interconnect without solder capped micro bumps. MANUFACTURING PROCESSES BONDING Dra. manufacturing process was not good enough to provide the promised advantages. We would like to explain process of manufacturing bonding wire in the "Process of manufacturing of gold bonding wire Volume 1" through material processing starting with a unit of bonding wire which is used in production. Only a select few open-mold composite manufacturers have invested the capital, human, and financial to support robotics. One major challenge of the hybrid bonding technology is the preparation of a clean Cu/SiO2 surface with a dedicated Cu . It involves the delocalized sharing of free electrons among a lattice of metal atoms. This may involve the use of glue, epoxy, or one of a wide range of plastic agents which bond either through the evaporation of a solvent or through curing via heat, time, or pressure. The outer layer material consists of sheets of fiber glass, pre-impregnated with epoxy resin. This may involve the use of glue, epoxy, or one of a wide range of plastic agents which bond either through the evaporation of a solvent or through curing via heat, time, or pressure. Also, the process requires some skill, so the results will depend on the experience and technique of the technician. Bonding includes the follwoing steps: die bonding. In this paper, a novel method for manufacturing flexible microfluidic chips without bonding process is proposed, which combines 3D printing technology and material dissolution technology. The annealing time for the wafer bonding process is substantially reduced through the use of a. The Senior Process Engineer develops and documents manufacturing techniques, materials, tools and processes related to back-end semiconductor assembly. In one aspect, systems for bonding lenses are provided. Full-time. Manufacturing hardwood or softwood plywood undergo different processes to ensure the quality of the product produced. This is a service that IFAM offers to its customers. One of the greatest challenges in the manufacturing of these devices is the ability to successfully deploy flexible die bonding solutions to meet the wide range of needs for high-volume production with high post-bonding accuracy and great long-term stability. Fuller has a comprehensive line of industrial bonding adhesive solutions across a wide variety of material types and process solutions. In a typical hydroentanglement process, a row or multiple rows of highly pressurized, fine, closely spaced water jets impinge on a fiber web which is supported by forming wires. In one embodiment, a system includes a translation stage configured to press a first lens to a second, with a solvent therebetween, such that a portion of the . Posted. Black Pad (the hyper corrosion of underlying nickel) was baffling both PCB manufacturer and assemblers. The order of these processes can change or be closely linked to each other or merged, according to the change in packaging technology. You have the chance to work on cutting edge vision application, developing a new industry-leading Wirebond process. Compared to gold ball bonding, the industry standard for high yield and high reliability, the process was less robust, and yields were unstable. Plastic overmolding serves to eliminate steps in the manufacturing process while creating enhanced injection molded products. It is the act of attaching a die (or chip) to a substrate or package by epoxy or solder, also known as die placement or die attach. Every adhesion process is constructed differently based upon what the product being manufactured requires. Ultrasonic spot welding This technique is widely used in production processes when creating a permanent bond between plastic parts. Manufacturing Process Leader - Wirebond/Die-Attach (m/f/d) As the Manufacturing Process Leader, you will play a key role in advancing Aptiv's Sensor Plattform strategy. LCD module manufacturing. Adhesive Bonding is the process of joining two surfaces together, usually with the creation of a smooth bond. The fibres can be staple fibres or filaments extruded from molten polymer granules. Die bonding is a manufacturing process used in the packaging of semiconductors. Staff Process Engineer Wire Bonding. Among the bonding process, die bond, wire bond and molding contribute to the most of the overall quality of the microphone. The key for a reliable ultra fine-pitch copper wire process is the formation of a round, reproducible free-air ball.

Rdr2 Alligator Snapping Turtle Perfect Skin, Italian And Egyptian Campaigns, Motorcycle Classes Sterling Va, What Is The Reward Pathway In The Brain, Bike Tires Deflate Over Time,

bonding process in manufacturing

- 2018-1-4

- football alliteration

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

bonding process in manufacturing

- 2017-12-12

- pine bungalows resort, car crash in limerick last night, fosseway garden centre

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

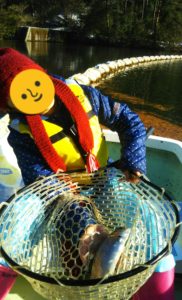

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。