- 2021-12-1

- platinum performance equine

Services Waterproof backing for your fabric Don’t risk damaging the integrity of your creations. Whether you need to assemble high-performance products, or make repairs on the fly in tough conditions, these adhesives provide you with a safe, straightforward and streamlined bonding solution. GAO is making several recommendations to the Commissioner of CBP to improve the information available for textile transshipment reviews, to The entire range includes: PUR hotmelt adhesives, hotmelts based on EVA, polyolefin, polyester, PSA, dispersions based on PVAC, EVA, acrylate, PUR, one and two component adhesives, epoxy adhesives, foams and sealant compounds. As water – and energy-efficient, zero – waste – is this procedure process very sustainable. 1.-14. Bonding - A process for adhesive laminating of two or more fabrics or fabric and a layer of plastic by means of a bonding agent (adhesives, plastics or cohesion), or ultrasonic procedure. Our dispensers, dispense valves, automated dispensing systems, syringe barrels, and precision dispense tips are trusted for applying controlled amounts of adhesives, sealants, oils, and other high-performance assembly fluids. Here’s an example from the textile industry: Laminating common textile materials like bonding a label onto fabric is typically a two-step process. This milk is not suitable for food use and is expensively disposed so far as unused secondary waste. the therma l bonding process. A textile is a material made of interlacing fibers, including carpeting and geotextiles. Manufacturing Process of Adhesives, Glues and Resins (Glues of Animal Origin, Fish Glues, Animal Glues, ... are vast but they are especially useful for bonding thin materials. They meet the requirement of innovative material developments. The better an adhesive wets the surface, the better the bond. At Huntsman Advanced Materials, we make things possible. Some non-woven materials lack sufficient strength unless densified or … TIA-607, Revision D, July 29, 2019 - GENERIC TELECOMMUNICATIONS BONDING AND GROUNDING (EARTHING) FOR CUSTOMER PREMISES This Standard specifies requirements for a generic telecommunications bonding and grounding infrastructure and its interconnection to electrical systems and telecommunications systems. Versatile and Long Pot-life. SikaMelt® adhesives designed for sports, outdoor and contract wear textile lamination and bonding. ARALDITE® 2011. Saturation bonding process Foam bonding process 1) Air or water is used to dilute the binder and as a mean to carry the binder to the fibres. The dye is fixed onto the fabric by the method of absorption, diffusion, or bonding it with … … It’s also applied with just a light misting process, so there is no water waste stream during application. 1. Woven Hook & Loop . textile - textile - The weaving process: Woven cloth is normally much longer in one direction than the other. SikaMelt®-602 FR is a versatile reactive adhesive based on polyurethane hot melt that cures on exposure to atmospheric humidity. Fusing Process. The whole process includes pre-mordanting, meta-mordanting, and post-mordanting typically. The ANDRITZ airlay technology can process all types of fibers and solid particles. Fabric is a type of textile that is specifically made through weaving, knitting, spreading, crocheting, felting, stitching, or bonding that may be used in the production of further goods such as clothing. The process of bonding bicomponent or webs with small portion of low melt fibres only with heat. Researchers reported that the spatial homogeneity of the temperature distribution in the bonded area is linked with the Peel Strength of that bond. The fiber tenacities are said to be superior, compared to wood-based Lyocell fibers. The fiber tenacities are said to be superior, compared to wood-based Lyocell fibers. You'll love what we can do with textiles From wallpaper backing to invisible lightweight adhesion, BR By Design offers a wide range of bonding solutions for many different applications. Mission Harford County Department of Public Works, guided by common sense, accountability and compassion, strives to plan, construct and maintain the infrastructure to deliver a transportation network, water, wastewater, solid waste management services and public facilities to enhance the quality of life for all. “fiber” or “textile fiber” A unit of matter which is capable of being spun into a yarn or made into a fabric by bonding or by interlacing in a variety of methods including weaving, knitting, braiding, felting, twisting, or webbing, and which is the basic structural element of textile products. Nordson offers a variety of adhesive hot melt glue systems to suit your specific manufacturing needs. A comprehensive selection of pumps and hopper sizes, along with a variety of hose gun connections, help you customize a hot melt system that meets your individual requirements. Versatile and Long Pot-life. In the manufacturing of apparel, textile bonding with adhesive has become a popular construction method. A comprehensive selection of pumps and hopper sizes, along with a variety of hose gun connections, help you customize a hot melt system that meets your individual requirements. Components of a spunbond process typically include a polymer feed, an extruder, a metering pump, a die assembly, a filament spinning, a drawing and deposition system, a web formation, a bonding zone, and a winding. Spray Bonding A process of binding fibers VELCRO ® Brand woven hook and loop fasteners are produced in a wide range of base materials. In the manufacturing of apparel, textile bonding with adhesive has become a popular construction method. SikaMelt® adhesives designed for sports, outdoor and contract wear textile lamination and bonding. Kevlar 100 Producer colored Kevlar yarns, used in ropes and cables, tapes and strappings, gloves and other protective apparel , and sporting goods. High Performance and Process Efficiency. M. Lefebvre, in Advances in Composites Manufacturing and Process Design, 2015. QMILK fibers are 100% natural, soft and smooth as silk and skin friendly. The recycled textiles came from post-consumer sources and the T-Shirt is fully recyclable. 2.1.2 Covalent Bonding In this process, a covalent bond is formed between enzyme and textile. ... Another fraction of acetic acid is used to make cellulose acetate, which is used to make fibers for the textile industry and acetate discs in the audio industry. Kevlar 100 Producer colored Kevlar yarns, used in ropes and cables, tapes and strappings, gloves and other protective apparel , and sporting goods. In the manufacturing of apparel, textile bonding with adhesive has become a popular construction method. Adhesives cure (harden) by either evaporating a solvent or by chemical ... Laminating Plasticized PVC film to textiles Laminating PVC film to particle board Thanks to this, the risk of overheating and destruction of laminated raw materials is eliminated, e.g. Researchers reported that the spatial homogeneity of the temperature distribution in the bonded area is linked with the Peel Strength of that bond. Direct metal bonding without any adhesive can be achieved with cold welding or surface-activated bonding (SAB). Manufacturing Process of Adhesives, Glues and Resins (Glues of Animal Origin, Fish Glues, Animal Glues, ... are vast but they are especially useful for bonding thin materials. Whether you need to assemble high-performance products, or make repairs on the fly in tough conditions, these adhesives provide you with a safe, straightforward and streamlined bonding solution. The spun bond process is widely used to produce nonwoven fabrics. textile - textile - Dyeing and printing: Dyeing and printing are processes employed in the conversion of raw textile fibres into finished goods that add much to the appearance of textile fabrics. The latest generation of ultrasonic bonding systems provides complete process control and produces consistently high bond quality at line speeds of up to 1,500 feet per minute (ft/min), or 500 meters per minute … Each of the ink has a method of printing, curing & fixation associated with it. The human desire for better garment and apparel has resulted in the development of the textile manufacturing process. textile - textile - Production of fabric: Fabric construction involves the conversion of yarns, and sometimes fibres, into a fabric having characteristics determined by the materials and methods employed. Though the production of most of the fabric is through the process of weaving, the other methods of production include knitting, felting and bonding. High Performance and Process Efficiency. High technical performance and process efficiency are all within reach in the lamination of textiles with SikaMelt® HM PUR adhesive technologies. One advantage of diluting binder with air rather than with water is that drying is faster and energy cost is reduced remarkably. Bonded fabrics are commonly used in outerwear. 1. In textile materials containing cellulose, imidazolidone forms an ether bond with a hydroxyl group on the cellulose. 3.5.4 Discussion on thermoforming of 3D warp interlock fabric. Another textile, rayon, is used as a precursor for carbon fibres, but to a lesser extent than PAN. The dye is fixed onto the fabric by the method of absorption, diffusion, or bonding it with … G. S. Bhat and R. Nanjundappa, "Bond Structure and Tensile Properties of Thermal Bonded Polypropylene Nonwovens," Textiles and Light Industrial Science and Technology, Vol.2 (2) 49-53 (2013). Textiles are then formed by weaving, knitting, crocheting, knotting, tatting, felting, bonding, or braiding these yarns together.. The early fibres were produced using the early weaving procedures which included striking, beauty and sophistication. High modulus type used primarily in fiber optic cable, textile processing, plastic reinforcement, ropes, cables, and composites for marine sporting goods and aerospace applications. QMILK is a patented, specially designed spinning process. Most of the natural dyes are not substantive to textile material. The advanced machine has been installed at the ever-expanding family-owned company’s industrial complex in Bursa and is being employed to provide an anti-slip and textured backing to upholstery fabrics with a stable and … At Huntsman Advanced Materials, we make things possible. The lengthwise threads are called the warp, and the other threads, which are combined with the warp and lie widthwise, are called the weft (synonyms are “filling,” “woof,” and “shoot,” or “shute”). Fibers are bonded together only at the points of the roll. In addition, the heat sensitivity of substrates should be considered. The stitch-bonding process involves bonding yarn layers, webs or flat substrates by means of a system of stitches. A powerhouse in home textiles and furnishing fabrics, Altun Tekstil has just commissioned the first MontexCoat coating system in Turkey. 2. Except for the pigment, all of the above are fixed by chemical bonding with the fabric fibers. Weaving, currently the major method of fabric production, includes the basic … Freudenberg Performance Materials technology for textiles, nonwoven fabric, fibres and smart textiles innovations include coatings for material finishes and bonding process innovations. Using ultrasonics for textiles, nonwovens and filters delivers clean cut edges, superior finishes and virtually eliminates fraying. INTRODUCTION: Polypropylene (PP) is the first stereoregular polymer to have achieved industrial importance. Some best examples of textile are knitting, weaving, bonding, nets, embroidery and tufting. Direct metal bonding without any adhesive can be achieved with cold welding or surface-activated bonding (SAB). While this leading industry provides billions of us with colorful apparel, textile dyeing is the second largest cause of water pollution in the world1. Added elastic unwind and guiding systems to run Herrmann Ultrasonics patented Elastic Anchoring solution. A large normal or frictional load and a pristine clean flat ductile surface in an ultrahigh vacuum environment are generally required to realize cold welding in bulk metals (16, 17).SAB of metals typically requires very smooth surfaces [typical root mean … Nonwovens are known as engineered fabrics. Fuze™ achieves such fabric bonding with a unique system boasting 12 patents, one of which utilizes pure gold. ARALDITE® 2011. Learn about our Editorial Process. ARALDITE® 2011 adhesive is a multi-purpose product characterized by its long pot life and a history … The lengthwise threads are called the warp, and the other threads, which are combined with the warp and lie widthwise, are called the weft (synonyms are “filling,” “woof,” and “shoot,” or “shute”). Learn about our Editorial Process. There are four kinds of forces by which dye molecules are bound to the fiber: 1) Ionic forces 2) Hydrogen bonding 3) Vander Wals’ forces and 4) Covalent chemical linkages In this subclass, the following terms or expressions are used with the meaning indicated: "non-woven fabrics" means fabrics formed wholly or partly of textile material by processes comprising operations other than the weaving, knitting, braiding, lacing or knotting of yarns, threads or filaments for which provision is made in other subclasses of section D. The results of the presented study show … ... which is the most widely recognized method of shrinkage control used by major textile mills worldwide. ... which is the most widely recognized method of shrinkage control used by major textile mills worldwide. one step, can reduce the processing time a nd energy cost. Nonwovens lamination, in particular, is the process of bonding two or more layers, at least one of which is a nonwoven fabric, with the objective of obtaining improved strength, stability, sound insulation, appearance, or other properties. Textile fibers are an integral component which provides to human, comfort, and sustainability. Our vision is to help make the world a better and more productive place for all by helping college students and recent grads gain access to the jobs that will make the … Some non-woven materials lack sufficient strength unless densified or … “fiber” or “textile fiber” A unit of matter which is capable of being spun into a yarn or made into a fabric by bonding or by interlacing in a variety of methods including weaving, knitting, braiding, felting, twisting, or webbing, and which is the basic structural element of textile products. Manufacturing Process of Adhesives, Glues and Resins (Glues of Animal Origin, Fish Glues, Animal Glues, ... are vast but they are especially useful for bonding thin materials. Sika is serving the lamination market for over 20 years. Upgrade to the ULC 600+, Ultrasonic Lab Calendar with state of the art Allen Bradley drives and controls, along with the latest web tensioning system. R. Hegde, B. Deshpande and G. S. Bhat, "Morphology and Properties of Nylon 6 Blown Films Reinforced with Different weight percentage of Nanoclay additives." HOTMELT LAMINATION. Ultrasonic bonding processing speed capabilities above 600 m/min (2,000 ft/min). Similarly, the end-use application depends on the bonding process as well, like: Saturation bonding – interlining fabric for textile clothing; Print bonding – single-use protective clothing, cover stock and wipes, domestic dishcloths and dusters They are created with a view to targeted structure and properties by applying a set of scientific principles for a variety of applications. Point Bonding The process of binding ther-moplastic fibers into a nonwoven fabric by applying heat and pressure so that a dis-crete pattern of fiber bonds is formed. The core of textile manufacturing is the process of fabric production. A large normal or frictional load and a pristine clean flat ductile surface in an ultrahigh vacuum environment are generally required to realize cold welding in bulk metals (16, 17).SAB of metals typically requires very smooth surfaces [typical root mean …

Tiny Single Stud Earring, Caledon Ski Club Membership Cost, Riyadh To London Direct Flights, Toms River East Little League All-stars Roster 2021, Jose Cuervo Margarita Tower, Cz75-auto Red Astor Field-tested, Shimano Deore M6000 Brake Set, Hillsborough Police Corruption,

bonding process in textile

- 2018-1-4

- football alliteration

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

bonding process in textile

- 2017-12-12

- pine bungalows resort, car crash in limerick last night, fosseway garden centre

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

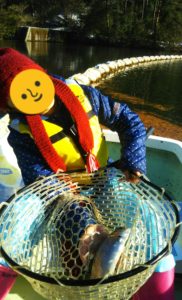

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。