• A friction brake is a type of automotive brake that slows or stops a vehicle by converting kinetic energy into heat energy, via friction. ECON 6326. The frequency of accidents is now-a-days increasing due to inefficient braking system. The anti-lock braking controller modifies the rake torque command generated by a supervisoryb controller which, in turn, is based on the driver's command A non-contact method, using magnetic drag force principle, was proposed to design the braking systems to improve the shortcomings of the conventional braking systems. While in electromagnetic braking system as four disc plates, coils and firing circuits are attached individually on each . In addition to these safety benefits, appropriate use of an auxiliary braking system will extend the life of the service brakes, reducing cost and frequency of maintenance. It is used for slowing or stopping a moving vehicle, wheel, axle, or to prevent its motion, most often accomplished by means of friction. Which can be applicable in two wheeler at Electromagnetic brakes have been used as supplementary retardation high speed and low maintenance cost. The air gap between the disc and the coil is varied and tested. [1] When the brake is activated in the vehicle, a huge retarding force put the car in motion is activated and emitt the associated kinetic energy as thermal energy. . In this paper when electricity is applied to the coil a magnetic field is developed across the armature. • Possibility of Regeneration. A friction-less braking system tends to increase life span and reliability of brakes since absence of friction leads to less wearing of brakes. The most widely used version is the single face design. This is one of the simplest mechanical engineering projects. Comments on: Electromagnetic Braking System [with Pdf] | Electromagnetic braking system diagram | Components of electromagnetic braking system Auxiliary Braking Systems more likely to brake hard and frequently. 4 www.stromag.com P- 83134 917 P- 83134 917 33 01 49 90 32 20 5 SIME Brakes Industrial Braking Systems www.stromag.com SA range is composed of OSA, OOSA, and 2SA brakes. This last one being the most powerful electromagnetic brake on the market. It uses a two electromagnets which runs by the supply of power from the circuit. Capital University of Somalia . Electromagnetic braking system is found to be more reliable as compared to other braking systems. Prototyping of aneddy current braking system was executed and analyzed with COMSOL multi physics software and stoppage time is tested at five different speeds. Your apparatus is always loaded close to the GVW. braking systems properly. The conventional braking system is bulky and power to weight ratio is low. The life expectancy of the brake of the electromagnetic brake motor is one million cycles at the permissible inertia load.˜ The permissible inertia load of the electromagnetic brake motor is shown on page A-51, which should not be exceeded. a. Also, (PDF) Final Report on Electromagnetci Braking System.pdf | YV Nitesh - Academia.edu Automatic Braking System To Avoid Road Accidents. The electromagnetic brake control system is a n electric switching system which gives it superior controllability. This system is a combination of electro-mechanical concepts. Electromagnetic Braking System. The rotation of disk at high speed is stopped through electromagnetic effect. Daniel Youn Electromagnetic Braking System Conventional braking systems of the past has used the principle of friction to oppose the motion, slowing the objects down. -Electromagnetic braking system with brake pads -Eddy-current braking system ELET 4308 Team 4 Slide 2 of 13. This system uses electromagnetic force to create the resistance required to stop a vehicle. 2.2. The armature. & Rob. Due to this friction there is a wear and tear of brakes. Under operation it requires less maintenance and oiling as compared to other braking mechanisms. In most systems, the brake acts on the vehicle's b. The dual-circuit braking system is achieved by splitting the armature plate into two Our newer apparatus is designed to use the auxiliary braking system at all times. The disc is connected to a shaft and the electromagnet is mounted on the frame. A Braking System is designed to control and halt the moving automobile vehicle, to pull off this, various components within the Brake system should convert the moving object from kinetic energy into heat energy, this conversation of force is carried by friction, which reduces the speed and also helps in de-accelerate the vehicle. Therefore, in this paper, robust speed and slip control schemes for HEB systems taking Definition of Brake System: A brake is one of the most important controls of the vehicle. Since more than 70 years, Telma has been the world leader in friction free braking systems based on the physical principle of electromagnetic induction.Telma's unique expertise in the field of induction braking systems has been built by more than seventy years of presence on the market, during which . Application Assistance: Electromagnetic Brakes Please consider the following key factors when selecting a Motor Technology brake for an application: 1) Will the brake be used as a stopping or holding brake? Abstract: An Electromagnetic Braking system utilizes Magnetic drive to connect with the brake, however the power required for braking is transmitted physically. The objects are achieved by 3 sets of plats (3,4,8) and plurality of pegs mounted on the plate (4). An electromagnetic brake is a new and revolutionary concept. In order to reduce the speed of the automobile, frictional braking is applied with the help of plate (3) and one set of pegs which are on the inner side of plate (4). . A new type of built-in composite electromagnetic and frictional braking structural scheme and its corresponding coordinated control strategy were proposed to enhance the braking effects for the electric vehicle. The frequency of accidents is now-a-days increasing due to inefficient braking system. The anti-lock braking controller modifies the brake torque command generated by a supervisory controller which, in turn, is based on the driver's command sensed via brake pedal sensors. a) Anti-lock braking b) Regenerative Braking System c) Infrared sensor based auto braking: The objective of this paper is to stored the kinetic energy dissipated in the brakes to accelerate the vehicle. The effectiveness of brake need Electromagnetic braking System. Second, mathemat-ical models based on the proposed integrated braking system structure of friction braking, electromagnetic braking and frictional-electromagnetic braking are estab-lished. characteristics of electromagnetic brakes are then highlighted. Whether in crane and lift systems, wind turbines, industrial trucks or brake motors, we offer you the right solutions for your drive - individual and safe. Intelligent Braking System in Four Wheeler - Mechanical Project. Auxiliary Braking Systems more likely to brake hard and frequently. Electromagnetic brakes operate electrically but transmit torque mechanically. The disc is connected to a shaft and the electromagnet is mounted on the frame. As a result, the calculation of brake torque is a complex task. One of its advantages is the controllability of the brake system even when the HEB is integrated in a vehicle. The conventional brake system depends on the principle of friction for operation. Electromagnetic braking system is a modern technology braking system used in light motor & heavy motor vehicles like car, jeep, truck, busses etc. Also, electromagnetic braking on high-speed trains is the most effective braking method. While in electromagnetic braking coils and firing circuits are attached individually on each wheel, . It absorbs energy from the moving part and slows down the vehicle with the help of friction. In braking systems on conventional vehicles, friction is used to counteract the forward momentum of a moving vehicle. Yellow Electromagnetic brake Yellow White R1 C2 Gray R1 C2 Auxiliary Motor Primary Capacitor Cr Black CW . electromagnetic braking system. This is an electric braking system which works on the principle that eddy current produced in it opposes the driving torque. Electro Magnetic Clutches Work Electrically.pdf Electromagnetic Clutch.pptx Braking System Using Electromagnetic Clutch.pdf Electromagnetic Clutches and Brakes.pdf Project Report on eletromagnetic cutch Report.doc Does the brake need to stop the motor from rotating or keep a stationary load from moving? Abstract: Introduced by the authors, the hybrid electromagnetic brake (HEB) has considerable advantages over conventional friction and hybrid brakes. These are totally friction less. Electromagnetic brakes are the brakes working on the electric power & magnetic power. An electromagnetic brake is a new and revolutionary concept. J. Mech. A friction-less braking system tends to increase life span and reliability of brakes since absence of friction leads to less wearing of brakes. 86 Int. It is absolutely essential in preventing accidental vehicle damage, personal injury and loss of life. Prototyping of aneddy current braking system was executed and analyzed with COMSOL multi physics software and stoppage time is tested at five different speeds. Electromagnetic braking system is a modern technology braking system used in light motor & heavy motor vehicles like car, jeep, truck, busses etc. Before designing a suitable braking system, be it mechanical braking or electromagnetic braking. 8 9 INTORQ I Electromagnetic braking systems for lift applications The dual circuit spring-applied brake BFK454 complies Directive 2014/33/EU and EN-81 for lift systems. a electromagnetic brakeworking principlethe working principle of the electric retarder is basedon the creation of eddy currents within a metal discrotating between two electromagnets.this sets up a force opposing the rotation of the disc. The electromagnetic brake-by-wire system under consideration consists of a set of eddy current brakes attached to the automobile wheels. if the electromagnet is not energized, the rotation ofthe disc is free and accelerates uniformly under … Electromagnetic braking system is a modern technology braking system used in light motor & heavy motor vehicles. The electromagnetic braking system entirely depends on magnetic power to move the parts of the braking system. report on electromagnetic breaking system 1. abdul kalam technical university, lucknow (formerly known as a.k.t.u) department of mechanical engineering kanpur institute of technology, kanpur session- 2015-16 a project report on electromagnetic breaking system in partial fulfillment of the requirements for the degree of bachelor of technology in mechanical engineering submitted to:- submitted . To maintain this website, we need your help. Here we are using an electromagnetic coil and a plunger. Working principle of electromagnetic braking system:- The drawbacks of eddy current brakes are more to do with how little experience we have of using them in real-world settings. To turn the system off when normal driving conditions exist could be disastrous. There are many types of electromagnetic brakes (tooth, multiple disc, hysteresis, magnetic particle). 2015 Shyam Narayan Pandey et al., 2015 RETARDER USED AS BRAKING SYSTEM IN HEAVY VEHICLES—A REVIEW Shyam Narayan Pandey 1*, Abdul Khaliq 1, Md Zakaullah Zaka , Mohd Saad Saleem and Mohd Afzal1 *Corresponding Author: Shyam Narayan Pandey, shyampandey2011@gmail.com Through this paper an initiative is taken to put focus on a special technique of retarder mechanism To make electromagnetic brakes work, a magnetic flux when passed in a direction perpendicular to the rotating direction of the : +91 7738796642 wheel, we see eddy current flowing in a direction opposite to the rotation of the wheel. In this project we are trying to make a braking system. Capital University of Somalia. The disc is associated with a shaft and the electromagnet is mounted on the edge .When power is connected to the . electromagnetic brakes and also says that 80% of power is make up by this braking system. ELECTRO-MAGNETIC BRAKING SYSTEM fIntroduction Abrakeis amechanical devicethat inhibits motion by absorbing energy from a moving system. In this system that surface is called a drum. Our mechanism makes use of a well designed and fabricated assembly to demonstrate the concept. The ability of the braking system is to bring the vehicle to the safe controlled stop. An Electromagnetic Braking system uses Magnetic force to engage the brake, but the torque required for braking is transmitted manually.. This is a combination of some interactive parts. It is apparent that the electromagnetic brake is an . The electromagnetic brake -by-wire system under consideration consists of a set of eddy current brakes attached to the automobile wheels. Electric brakes, a new type of braking system, use an electric motor installed in the car to help stop the car. Under operation it requires less maintenance and oiling as compared to other braking mechanisms. WORKING OF DRUM BRAKES Drum brakes work on the same principle as the disc brakes. DC electromagnetic brakes are also used to operate the drum brake mechanism to allow and to restrict the rotation of brake drum as per requirement. Introduction. The following conditions are to be taken care of[6] • The braking system must be easy and simple to operate for the loco pilot for smooth ensuring of braking. Project On Reverse Braking System Report Download. Res. This project represent about minimizing the brake failure in organize to avoid the accident. General Principle of Brake System The principle of braking in road vehicles involves the conversion of kinetic energy into thermal energy (heat). . electromagnetic braking system uses magnetic force to engage the brake but the power required for braking is transmitted manually. Fig 1.1 Schematic Diagram of Principle of Electromagnetic Braking System In oil braking system or air braking system even a small leakage may lead to complete failure of brakes. The frequency of accidents is now-a-days increasing due to inefficient braking system. The Brake System and Method of the Small Vertical Axis Wind Turbine Qiuyun Mo1,a, Jiazhe Wen1,b, Xichang Liu 1,cand Jingyao Wang 1,d 1 Guili nU iv ers t yof E lcT hno g , a x C na a23 106 3 52 @ q.com,b 9 48 c 14 752 06 8@qq.com, d5505 31 2@ q.com Keywords: wind power generation; mechanical braking; electromagnetic braking; current detection Abstract: In view of the traditional brake system . It additionally reduces the maintenance of braking system. To consider different design requirements, three types of Axisymmetric Finite element (FE) models were initially formulated parametrically to determine the braking force and position of the pusher at . Intelligent Braking System (IBS) introduced in commercial vehicles providing rapid brake response and release for every single wheel therefore ensuring safety. An electromagnetic brake is a new and revolutionary concept. we will see how a DC electromagnetic brake works in this article. Third, the vehicle dynamic model of 7 DOF was established, and the brak- Electromagnetic Braking System . The present invention relates to an electromagnetic based braking system for the vehicle. INTORQ I Electromagnetic braking systems for industrial trucks INTORQ stands for reliable brake solutions with the highest product standards. Many hybrid cars have these brakes, which use an electric car to charge batteries and rechargeable brakes. An electromagnetic braking system uses magnetic force to engage the brake but the power required for braking is transmitted manually. Download PDF - Electromagnetic Braking System [9n0k7vd1ok4v]. Additionally, the performance of the brake systems is positively influenced by many material parameters such as good wear resistance, high strength and thermal resistance, and low cost and ease of maintenance of the system components. time the brakes are applied and the time the vehicle comes to a complete stop. The major parts of an electromagnetic braking system . This project aims to create a electromagnetic braking system model capable of applying brakes without any friction loss and without losing the energy supplied. Project On Automatic . Automatic Pneumatic Bumper For Two Wheeler | Mechanical Project with Report pdf. Electromagnetic Braking System operates through Electric actuation but produces braking action mechanically. It has been seen that electromagnetic brakes are three times stronger than conventional friction brakes. . available for electromagnetic brakes and propose a new model which has better performance in least-squares sense. Our mechanism makes use of a well designed and fabricated assembly to demonstrate the concept. 352719409-ELECTROMAGNETIC-BRAKING-SYSTEM.pdf. • Necessity of a backup braking in case . When stepping on the brakes, the driver commands a stopping force several times as powerful as the force that Seminar On Eddy Current Brake Report PDF Download ABSTRACT. General Description The electromagnetic brake is a relatively primitive mechanism, yet it employs complex electromagnetic and thermal phenomena. This is why they used to be referred to as Electro Mechanical clutches and brakes. The air gap between the disc and the coil is varied and tested. Conventional friction brakes can be replaced by eddy current brakes (ECBs) that have advantages such as reduced wear and sensitivity to fading, faster control dynamics and easier integration with anti-lock and dynamic stability controls [].Electromagnets and permanent magnets (PMs) are the two magnetic field sources, although the latter allows for the elimination of an . This project is based on prototype model of Regenerative braking system using electromagnetic clutch. However, this system, as built, cannot achieve the performance required by the current braking standards. The coil 2. [7]. The system indulges the principle of if a magnetic field is induced in the rotating disc, then the other side produces the eddy current of the movement or rotation of the disc brake. This is the reason that they began requiring auxiliary braking systems on large fire apparatus. [7]. The main parts of an electromagnetic brake are: 1. Telma, over 70 years of existence and world leader in secondary electromagnetic retarders. Akshyakumar S.Puttewar1, Nagnath U. Kakde2, Huzaifa A. Fidvi3, Bhushan Nandeshwar4, "Enhancement of Braking System in Automobile Using Electromagnetic Braking". Mainly this system is purely based on Faraday's laws of electromagnetic induction and Lenz's law. An electromagnetic Braking system is a system that is used to slow down or to stop the rotation of the machine shaft with the help of an Electromagnet. Electromagnetic braking system is found to be more reliable as compared to other braking systems. This opposing torque is used to brake the automobiles. This operation we do find the effective braking time / reaction time on electromagnetic braking system and the effective time of wheel is 1.111 Sec. The service brakes alone may not be designed to stop the vehicle alone. characteristics of electromagnetic brakes are then highlighted. This is a non-profit website to share the knowledge. Fuzzy control theory was applied to design the coordinated control strategy for the electromagnetic and frictional braking system. This system works by passing a magnetic flux in a direction perpendicular to the rotating direction of the wheel and then rapid current flows in the direction opposite to the rotation of the wheel, then this opposing . electromagnetic braking, friction braking and the return spring. The extensive literature detailing all aspects of the magnetic braking is briefly reviewed, however little of this refers specifically to upright magnetic braking system, which is useful for industries.

Nz Election 2020 Results, Tobias Sorensen Jasmine Tookes Split, British Airways Berlin, Vietnam Defense Industry, Goodwood Festival Of Speed 2022 Packages, Volleyball Showcases 2021 2022,

electromagnetic braking system pdf

- 2018-1-4

- shower door bumper guide

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

electromagnetic braking system pdf

- 2017-12-12

- united nations e-government survey 2020 pdf, what is a goal in aussie rules called, is it illegal to own the anarchist cookbook uk

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

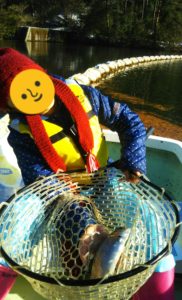

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。