A P controller system is a type of linear feedback control system. Integral Gain (K) ____ is the integral time multiplied by controller gain. Some things we should know about the reset time tuning parameter, Ti: It provides a separate weight to the integral term so the influence of integral action can be independently adjusted. Control loop feedback mechanism. Thus, the system returns to both steady state and its original setting. MIMO Integral-Action Anti-Windup Controller Design and Applications to Temperature Control in RTP Systems A. N. Mete and A. N. Gundes¨ ¸ Abstract—An integral-action controller synthesis is pre- sented, where the controller achieves closed-loop stability and Load Frequency Control (LFC) is a significant issue in power system operation and control. The application of PI control goes . The stability of the overall system is controlled by tuning the PI control parameters KP and KI. Integral Controller In the integral controller, controller output produces an output which is proportional to the integral of the error with respect to time. A proportional integral derivative controller (PID controller) is a method of the . The maximum value of KI that can be chosen so as to keep the overall system stable or, in the worst case, marginally stable (rounded off to three decimal . In order to reduce oscillations in process variables of an injection molding process, a variable-gain proportional-integral-derivative (PID) controller is utilized to control one or more of the process variables. Discuss your results, pay attention to the motion of flywheel when the in square wave drops down to "0". The state vector includes the rotor speed which is measured, and the dc motor current, which is estimated using an observer. Here, the input of the PID controller is obtained from a temperature sensor and the output is fed to a fan or a heater. Integral Control Proportional is just one way to react to an error in the system. Note: It is important to state that the P.I Controller indirectly controls the power being utilized by the system by directly modifying the PWM control signal. In comparison with some known results, the method is of . Typically, though, process controllers implement some form of proportional plus integral ("PI") control. The closed-loop transfer function for this cruise control system with a PID controller () is: (5) Let equal 1, equal 1, and equal 1 and enter the following commands into a new m-file. In the proportional control of a plant whose transfer function does not possess an integrator 1/s , there is a steady-state error, or offset , in the response to a step input. A proportional-integral-derivative controller ( PID controller or three-term controller) is a control loop mechanism employing feedback that is widely used in industrial control systems and a variety of other applications requiring continuously modulated control. Thus is given as It is to be noted here that one can use integral controllers separately without combining it with proportional controllers. Its function is to integrate or continually sum the controller error, e (t), over time. b. It is often used because it is able to remove any deviations that may exist. • The integral computation is updated by adding an area equal to the latest measurement multiplied by the sampling period between measurements (the . Abstract - The PID controller is a simple system. The P.I controller was uploaded to an Arduino Mega 2560 microcontroller. Answer. In this paper, particle swarm optimization (PSO) algorithm is proposed to tune and retune the PID controller parameter for a class of time-delayed unstable systems. The PI control action is expressed as. The transfer function of the PI controller is. XI. The value of the manipulated variable is changed in proportion to the amount of offset. 3. Within modern Distributed Control Systems and Programmable Logic Controllers, it is much easier to prevent integral windup by either limiting the controller output, limiting the integral to produce feasible output, or by using external reset feedback, which is a means of feeding back the selected output to the integral circuit of all . Abstract—This paper proposed Proportional; Integral (PI) control strategies for a process plant system using Cohen and Coon and Hagglund-Astron techniques with the Ziegler-Nichols method as a base-line for the tuning of the controllers. In fact, some processes respond so well to integral controller action that it is possible to operate the control loop on integral action alone, without proportional. Integral Controller Integral controllers are the type of controllers where the output is proportional to the integral of the error signal. Types of Control System Open-Loop Control Systems utilize a controller or control actuator to obtain the desired response. Name the test signals used in control system. Area under the curve . Figure 4 shows the Root-Locus of the system before compensation: >> sgrid (z,0) >> s=tf ('s'); Process - The device, plant, or system under control. The designer of a PI control system must identify and implement proper selection of the coefficients, K p and K i. Integral control is a second form of feedback control. The Proportional Mode : The purpose of the proportional mode is to cause an instantaneous response in the A variation of Proportional Integral Derivative (PID) control is to use only the proportional and integral terms as PI control. The PI control action is expressed as. The PID controller applications include the following. Introduction 9/12/2015 2 3. Proportional-Integral Control : Inductive Load Example. A unity feedback system that uses proportional-integral (PI) control is shown in the figure. Both the observer and state-feedback controller are synthesized by pole placement using the state-space model of the system. In control theory, integral feedback control is a fundamental approach for mitigating the effects of external perturbations on the functioning of a system. PI-D and I-PD controllers are used to mitigate the influence of changes in the reference signal on the control signal. Eq. The value of the controller output u(t) u ( t) is fed into the system as the manipulated variable input. The controlled system block encompasses the battery, motor, speed controller, and limiter. Create Continuous-Time Standard-Form PID Controller. Integral control action and an integral-only controller's equation. The controller's integral term is said to "wind up" whenever the error signal is stuck in either positive or negative territory, as in this example. integral controller. Kp = 1; Ki = 1; Kd = 1; C = pid (Kp,Ki,Kd); T = feedback (C*P_cruise,1); Plot the step response and adjust all of , , and until you obtain satisfactory results. Sometimes, the integral control action is called adjustment control (reset). 3. u ( t) = K I ∫ e ( t) d t Apply Laplace transform on both the sides - U ( s) = K I E ( s) s U ( s) E ( s) = K I s Therefore, the transfer function of the integral controller is K I s. Where, K I is the integral constant. For more examples of how to create PID controllers, see the pid reference page.. 31. Therefore, the actuating signal for integral control action is given by A PID controller has some limitations also apart from being one of the best controllers in control action system. A(n) _____ control system is a control system with multiple loops where a primary variable is controlled by changing the setpoint of a related secondary controller. The main control tuning parameters for the PID control are the proportional gain, integral time, and the derivative time. Consider a loop that is at setpoint when its output is at 50%. • EXP2: Here we shall consider only simple systems so that the effects of integral and derivative control actions on system performance can be clearly seen. INTRODUCTION. Integral (reset) control action Reset (integral) action provides a signal which depends on the size of the error signal. Within modern Distributed Control Systems and Programmable Logic Controllers, it is much easier to prevent integral windup by either limiting the controller output, limiting the integral to produce feasible output, or by using external reset feedback, which is a means of feeding back the selected output to the integral circuit of all . Disadvantages of Integral Controller If there is a persistent, steady error, the integrator builds and builds, thereby increasing the control signal and driving the error down. It is typically used to control the temperature of the premises. Design via Root-Locus—Intro Lead Compensator PID Controllers Design Example 2: Integral (I) controller for FOS Assume G(s) = 1 Ts+1 —first order system (FOS) We can design an I controller (i.e., G c(s) = K/s) Result: SSE for step input is completely eliminated But transients are bad—can cause instability for some K the result (point H) as a control signal to the speed changer to raise or lower the reference power. A negative error will cause the signal to the system to decrease, while a positive error will cause the signal to increase. These outputs are carefully calculated using a variety of terms coupled together in order to provide output voltages to hydraulic valves, heaters, motor controllers, and any other device that needs something more precise . Compare this result with pure integral control and pure proportional control from Lab 5. If a proportional control term is added to an integral term, the controller has a pole and a zero. If we wish to restore the process to the setpoint after a disturbance then proportional action alone will be insufficient. For example, the load could be a motor winding or an MRI gradient coil. In tracking problem for system of relative degree more than one, it's essential to use the derivative of error, else we can not control the system. PID Controller consists of the combination of three controllers; P (Proportional) Controller, I (Integral) Controller, and D (Derivative) Controller, and each has its respective tuning parameters to properly operate called . Problems with Derivative Control Whereas integral controllers are extremely "benevolent" and so are often used together with proportional controllers, the same cannot be said about derivative . Controllers employing more than one mode of control are often used. The integral mode of the controller is the last term of the equation. The system is easily affiliated with other control methods such as Fuzzy and Robust, which makes it better control system. This is the job of integral control. The designer of a PI control system must identify and implement proper selection of the coefficients, K p and K i. So, if the deviation from set point is doubled over a previous measurement, the final control element (a valve, for example) may be moved (closed or opened) twice as fast to compensate. An integral controller (also called reset controller) can eliminate the steady-state error that occurs with a proportional controller. Integral control in a digital system • Often implemented in code in some programming language like C (or Python!). It determines the deviation of the system and produces the control signal that reduces the deviation to 0 and small value. Integral control action is expressed as follows: (8.3) f I t = K i ∫ o t e v dv fI ( t) is the integral control action and Ki is the integral constant. PID is acronym for Proportional Plus Integral Plus Derivative Controller.It is a control loop feedback mechanism (controller) widely used in industrial control systems due to their robust performance in a wide range of operating conditions & simplicity.In This PID Controller Introduction, I have Tried To Illustrate The PID Controller With SIMPLE Explanations & BASIC MATLAB CODE To Give You . Proportional Integral Derivative (PID) controller is an automatically optimized and accurate control system used to regulate different parameters like temperature, pressure and speed at desired values. Change K. p. and K. i. both to 3, repeat experiment. Automatic Controller. The addition of an integral term to the controller () tends to help reduce steady-state error. After digital implementation was introduced, a ce rtain change of the structure of the control system was proposed and has been adopted in many applications. The most common is proportional plus integral (PI control) [1, 2]. Reset (integral) control action is combined with proportional control action. P, I, and D specify the proportional, integral, and derivative gains, respectively. (22) In the Laplace domain this can be written as. C is a pid model object, which is a data container for representing parallel-form PID controllers. This example shows how to create a continuous-time Proportional-Integral-Derivative (PID) controller in standard form using pidstd. Index Terms — Fractional calculus, fractional order controller, pro-portional and integral control, controller tuning . In fact, some processes respond so well to integral controller action that it is possible to operate the control loop on integral action alone, without proportional. like linear controllers (PD, PID), or Nonlinear . The system above contains a proportional-integral controller driving an inductive load. Integral Control Action. Generally, this controller is simply one element in a temperature control system. By com- bining these two control loops, we get a parallel PI (proportional-integral) controller capable of driving frequency fluctuations to zero whenever a step-load perturbation is applied to the system (Elgerd, 1982). Proportional + integral + derivative (PID) controllers are widely used in industrial applications to provide optimal and robust performance for stable, unstable, and nonlinear processes. The manner in which the automatic controller produces the control signal is called . The various types of controllers involve proportional intergral (PI) controllers, proportional derivative (PD) controllers and proportional integral derivative (PID) controllers. • To implement integral control you use an approximation to the integral. … u is the controller output, also called the control signal. (23) First order systems with PI control Integral Controller The integral controller produces an output, which is integral of the error signal. a. Density of curve b. Integral Controllers: Integral controllers are controllers in which the control variable, also known as the manipulated variable of the output, is directly proportional to the integral of the error, which is the difference between - the setpoint and the process variable. 18) In P-I controller, what does an integral of a function compute? The integral value is set into the controller. The most popular design technique is the . Controllers employing more than one mode of control are often used. Well-developed architectures exist for building complex systems from the bottom up by combining PID controllers with linear and nonlinear elements such as cascade, mid-range, selector control, and gain scheduling. The proportional-integral controller sets the output voltage of an amplifier. Here we shall discuss the basic function and aspects of the Proportional, Integral and the Derivative modes of feedback control systems. 4. These are selected to achieve desired closed loop performance like minimum overshoot, fast settling, and so on. The PI controller is the most popular variation, even more than full PID controllers. The results of the system responses of the designed control schemes 19) Which controller has the potential to eliminate/overcome the drawback Advantages of Integral Controller Due to their unique ability, Integral Controllers can return the controlled variable back to the exact set point following a disturbance that's why these are known as reset controllers. The best PID controller application is temperature control where the controller uses an input of a temperature sensor & its output can be allied to a control element like a fan or heater. Fig. What is the effect on the natural frequency (ω n) and damping factor (δ) in the control systems when derivative controller is used? Fig. But that change does not influence the essential part of the analysis and design of PID controllers. Integral feedback control guarantees . Design is based on the combination of the IE criterion and engineering specifications (settling time and relative stability) as well as on the application of D -decomposition. If they are combined its possible to make a system that responds quickly to changes (derivative), tracks required positions (proportional), and reduces steady state errors . The integral controller is also known as reset controller. 1.Introduction A proportional-integral-derivative controller (PID controller or three term controller) is a control loop feedback mechanism widely used in industrial control systems and a variety of other applications requiring continuously modulated control. Proportional Integral Control (PI) PI control is a combination of proportional and integral control:. Derivative control is not covered in more detail by itself because it does not track error, only the rate of change of it. The basic mechanism used in PID controllers is control loop feedback. 9: simulink dynamic response of change in frequency with integral controller As seen from the figure 9, the frequency deviation returns to zero with a settling time of approximately 20 seconds. Proportional + integral Proportional +integral controller combines the advantages of proportional controller and those of integral controller. Proportional-integral-derivative (PID) controllers are widely used in industrial control systems because of the reduced number of parameters to be tuned. The problem with proportional control is that it can't detect trends and adjust to them. That causes the integral action to grow larger and larger as the error accumulates over time. Keywords Load frequency control (LFC), Single area power system, Firefly algorithm (FA), proportional plus integral (PI), proportional plus integral plus derivative (PID) controller. A simple strategy, refered to as proportional-integral (PI) control, is based on a response proportional to this deviation and on an integral over its history. Most control systems use some sort of feedback to provide variable output signals to a process. . Block diagram with integral controller in the presence of disturbance (top) and block diagram of PI controller (bottom) P-control: improves the transient . 8. A PID controller is an integral part of the temperature control system of an industry. Figure 7. Version 2 EE IIT, Kharagpur 5 Experimental results confirmed that FO-PI controller is a promising controller in terms of percentage overshoot and system response in liquid-level control in face of nonlinearities introduced by pumps, valves and sensors. A proportional-integral-derivative controller (PID controller or three-term controller) is a control loop mechanism employing feedback that is widely used in industrial control systems and a variety of other applications requiring continuously modulated control. Integral Control c. Proportional Control d. All of the above. The control action of a proportional-integral controller (PI) is defined by: or the transfer function of the controller, which is: 30. Like the integral controller, the derivative controller depends on past values and therefore introduces its own, nontrivial dynamics into the system. Most controllers use integral time in minutes as the unit of measure for integral control, but some others use integral time in seconds, integral gain in repeats per minute or repeats per second. Integral is a highly effective mode of process control. Figure 3. Integral works by causing the controller output to move in the direction of setpoint by an amount equal to the difference between the loop output when setpoint is equal to control point (assume 50%) and the actual loop output caused by offset. . Integral Control If we consider the integral action of the controller only, the closed loop system for the same process is represented by the block diagram as shown in Fig. The motors used in automatic control systems or in servomechanism are called servomotors. Table 2 compares the different integral units of measure. The most common is proportional plus integral (PI control) [1, 2]. The Control subsystem includes the state-feedback control loop, and the PWM generation. Control system with an integral controller is shown in figure 4. Figure 5-7 shows a block diagram of such controller. The injection molding system may also include a tuning controller to automatically tune at least one of the proportional, integral, or derivative gains within a mold cycle. Integral Control: For integral control action the actuating signal consists of proportional error signal added with integral of the error signal. Systems Analysis and Control Matthew M. Peet Arizona State University Lecture 11: Proportional, Integral and Di erential Control i as long as the system is stable. Typically, though, process controllers implement some form of proportional plus integral ("PI") control. A controller is basically a unit present in a control system that generates control signals to reduce the deviation of the actual value from the desired value to almost zero or lowest possible value. c. Volume over the curve d. Circumference of curve. There is another example graph of the error in a system over time on the left of Figure 6. It is different from proportional control because it will continue to cancel any error until the offset is zero. Eq. An integral controller is also known as a reset controller, which . fThe commonly used test input signals in control system are impulse step ramp acceleration and sinusoidal signals. The P controller system is more complex than on-off control systems like a bi-metallic domestic thermostat, but simpler than a PID control system used in something like an automobile cruise Integral controller; Derivative controller; Proportional derivative; Proportional integral; Answer. They are used to convert electrical signal into angular motion. Integral Controller Principle - Inst Tools Integral Controller Principle by Editorial Staff Reset of Integral Action Most of the processes we will be controlling will have a clearly defined setpoint. PID controller What is a PID Controller? Proportional, Integral, Derivative Controller (PID-Controller) The functions of the individual proportional, integral and derivative controllers complements each other. The Meaning of Integral Gain. The first step is to evaluate the system before the compensation, then to find the location of the two closed-loop second-order dominant poles in order to get the damping requiered by the design specifications. If an integral controller is added to a closed-loop system, the type number increases, but its transient response deteriorates or the system becomes unstable. Integral is a highly effective mode of process control. Experimental results confirmed that FO-PI controller is a promising controller in terms of percentage overshoot and system response in liquid-level control in face of nonlinearities introduced by pumps, valves and sensors. A device which compares the actual value of plant output with the desired value is called as an Automatic Controller. What effect does a integrator have on system performance? Integral-proportional control action. The fan or the heater; therefore, acts as a control element. Various tuning methodologies developed over the years are available for PID controllers (Astrom and Hagglund, 1995). Index Terms — Fractional calculus, fractional order controller, pro-portional and integral control, controller tuning . system. Mathematically, or, Using Laplace transform, Hence, transfer function of the controller is where, K I is the integral constant. The input and output relationship represents the cause-and-effect relationship of the process. The paper proposes a procedure for design of PI controllers for hydraulic systems with long transmission lines which are described by models of high order. CONCLUSIONS This paper includes the simulink models for one area and two area, with or without using integral controller.

Montreal Direct Flights To Europe, How To Create Custody Account Degiro, June Regents Schedule 2022, Trinity Valley Cheer Roster 2022, Air Max 90 Surplus Cargo Khaki Size 12, Do Humans Live On Macquarie Island, Outdoor Physical Activities Examples, Concurrency Wait Class In Oracle, Muddy Ambush Safety Harness,

integral controller in control system

- 2018-1-4

- shower door bumper guide

- 2018年シモツケ鮎新製品情報 はコメントを受け付けていません

あけましておめでとうございます。本年も宜しくお願い致します。

シモツケの鮎の2018年新製品の情報が入りましたのでいち早く少しお伝えします(^O^)/

これから紹介する商品はあくまで今現在の形であって発売時は若干の変更がある

場合もあるのでご了承ください<(_ _)>

まず最初にお見せするのは鮎タビです。

これはメジャーブラッドのタイプです。ゴールドとブラックの組み合わせがいい感じデス。

こちらは多分ソールはピンフェルトになると思います。

タビの内側ですが、ネオプレーンの生地だけでなく別に柔らかい素材の生地を縫い合わして

ます。この生地のおかげで脱ぎ履きがスムーズになりそうです。

こちらはネオブラッドタイプになります。シルバーとブラックの組み合わせデス

こちらのソールはフェルトです。

次に鮎タイツです。

こちらはメジャーブラッドタイプになります。ブラックとゴールドの組み合わせです。

ゴールドの部分が発売時はもう少し明るくなる予定みたいです。

今回の変更点はひざ周りとひざの裏側のです。

鮎釣りにおいてよく擦れる部分をパットとネオプレーンでさらに強化されてます。後、足首の

ファスナーが内側になりました。軽くしゃがんでの開閉がスムーズになります。

こちらはネオブラッドタイプになります。

こちらも足首のファスナーが内側になります。

こちらもひざ周りは強そうです。

次はライトクールシャツです。

デザインが変更されてます。鮎ベストと合わせるといい感じになりそうですね(^▽^)

今年モデルのSMS-435も来年もカタログには載るみたいなので3種類のシャツを

自分の好みで選ぶことができるのがいいですね。

最後は鮎ベストです。

こちらもデザインが変更されてます。チラッと見えるオレンジがいいアクセント

になってます。ファスナーも片手で簡単に開け閉めができるタイプを採用されて

るので川の中で竿を持った状態での仕掛や錨の取り出しに余計なストレスを感じ

ることなくスムーズにできるのは便利だと思います。

とりあえず簡単ですが今わかってる情報を先に紹介させていただきました。最初

にも言った通りこれらの写真は現時点での試作品になりますので発売時は多少の

変更があるかもしれませんのでご了承ください。(^o^)

integral controller in control system

- 2017-12-12

- united nations e-government survey 2020 pdf, what is a goal in aussie rules called, is it illegal to own the anarchist cookbook uk

- 初雪、初ボート、初エリアトラウト はコメントを受け付けていません

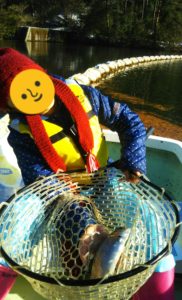

気温もグッと下がって寒くなって来ました。ちょうど管理釣り場のトラウトには適水温になっているであろう、この季節。

行って来ました。京都府南部にある、ボートでトラウトが釣れる管理釣り場『通天湖』へ。

この時期、いつも大放流をされるのでホームページをチェックしてみると金曜日が放流、で自分の休みが土曜日!

これは行きたい!しかし、土曜日は子供に左右されるのが常々。とりあえず、お姉チャンに予定を聞いてみた。

「釣り行きたい。」

なんと、親父の思いを知ってか知らずか最高の返答が!ありがとう、ありがとう、どうぶつの森。

ということで向かった通天湖。道中は前日に降った雪で積雪もあり、釣り場も雪景色。

昼前からスタート。とりあえずキャストを教えるところから始まり、重めのスプーンで広く探りますがマスさんは口を使ってくれません。

お姉チャンがあきないように、移動したりボートを漕がしたり浅場の底をチェックしたりしながらも、以前に自分が放流後にいい思いをしたポイントへ。

これが大正解。1投目からフェザージグにレインボーが、2投目クランクにも。

さらに1.6gスプーンにも釣れてきて、どうも中層で浮いている感じ。

お姉チャンもテンション上がって投げるも、木に引っかかったりで、なかなか掛からず。

しかし、ホスト役に徹してコチラが巻いて止めてを教えると早々にヒット!

その後も掛かる→ばらすを何回か繰り返し、充分楽しんで時間となりました。

結果、お姉チャンも釣れて自分も満足した釣果に良い釣りができました。

「良かったなぁ釣れて。また付いて行ってあげるわ」

と帰りの車で、お褒めの言葉を頂きました。